You encounter polyacrylamide and DADMAC in many essential processes that keep water clean and industries running efficiently. These chemicals help clarify water, improve industrial productivity, and support innovations in fields such as biomedical engineering and electronics.

Application Area | Polyacrylamide Uses | DADMAC Uses |

|---|---|---|

Wastewater Treatment | Effective in removing contaminants and improving water clarity | |

Paper Industry | Acts as a binder and fiber retainer | Used in copolymer synthesis for retention and drainage aids |

Agriculture | Enhances soil aeration and reduces water requirements | N/A |

Mining Industry | Improves solid-liquid separation in mineral extraction | N/A |

Textile Industry | N/A | Used for color removal and dye fixation |

Oil and Gas | N/A | Used in produced water treatment |

● Polyacrylamide is a powerful flocculant that helps clarify water by binding particles together, making it essential for effective water treatment.

● DADMAC acts as a cationic coagulant, improving wastewater treatment and enhancing paper production by helping particles settle and retain fine materials.

● Combining polyacrylamide and DADMAC in hybrid systems boosts flocculation efficiency, making it easier to remove contaminants in challenging industrial processes.

You rely on polyacrylamide to achieve high levels of water clarity in both municipal and industrial settings. This polymer acts as a flocculant, binding suspended particles together so they settle out of the water more efficiently. When you add polyacrylamide to water, it forms bridges between fine particles, creating larger aggregates that are easier to remove. This process dramatically reduces turbidity and improves the quality of treated water.

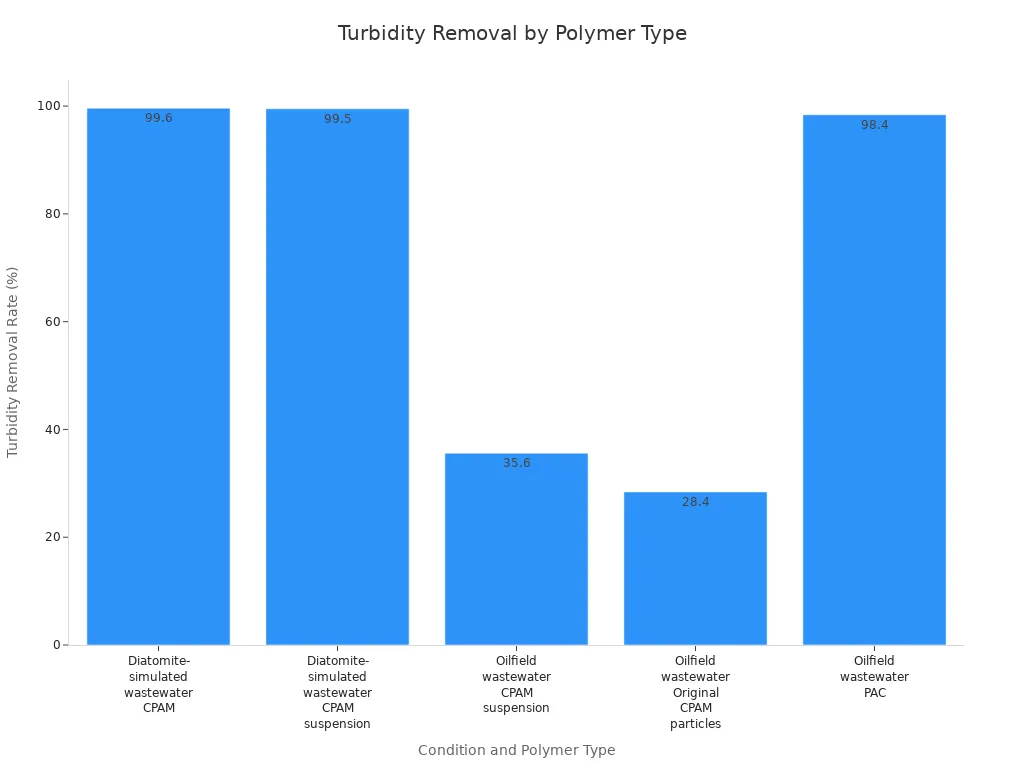

The effectiveness of polyacrylamide in removing suspended solids has been demonstrated in various scientific studies. For example, cationic polyacrylamide (CPAM) achieved a turbidity removal rate of over 99% in diatomite-simulated wastewater at a dosage of just 4 ppm. In oilfield wastewater, CPAM suspensions also outperformed traditional coagulants at much lower dosages.

Condition | Polymer Type | Dosage (ppm) | Turbidity Removal Rate (%) |

|---|---|---|---|

Diatomite-simulated wastewater | CPAM | 4.00 | 99.60 |

Diatomite-simulated wastewater | CPAM suspension | 4.00 | 99.50 |

Oilfield wastewater | CPAM suspension | Optimal | 35.60 |

Oilfield wastewater | Original CPAM | Optimal | 28.40 |

Oilfield wastewater | PAC | 140.00 | 98.40 |

Municipal water treatment plants typically use polyacrylamide at dosages ranging from 1 to 50 mg/L. You benefit from this efficiency because polyacrylamide requires much lower dosages than traditional flocculants, which means less sludge production and lower operational costs. Unlike aluminum or iron salts, polyacrylamide does not generate large volumes of silt, making the treatment process cleaner and more sustainable.

Tip: When you select a polyacrylamide for water treatment, consider factors such as ionic character, molecular weight, and charge density. Proper dosage and mixing are crucial for optimal performance.

You find DADMAC, especially in its polymerized form (polyDADMAC), essential for treating wastewater and improving paper production. In municipal and industrial wastewater treatment, DADMAC acts as a cationic coagulant. It destabilizes negatively charged particles, allowing them to aggregate and settle out of the water. This process helps you achieve clearer effluent and meet regulatory standards.

In the pulp and paper industry, polyDADMAC serves as a retention and drainage aid. When you use recycled fibers or aim for high-quality paper, polyDADMAC helps retain fine particles and fillers, improving both efficiency and product quality. The industry's shift toward sustainable practices and recycling has increased the demand for DADMAC-based solutions. You also benefit from improved drainage, which speeds up production and reduces energy consumption.

Recent studies confirm the effectiveness of combining acrylamide and DADMAC to create cationic flocculants. These hybrid polymers enhance flocculation in industrial processes, supporting your efforts to produce cleaner water and higher-quality paper.

You encounter polyacrylamide and DADMAC across a wide range of industries. In mining, you use polyacrylamide to separate minerals from waste and to dewater sludge. This application helps you comply with environmental regulations and improves operational efficiency. In oil recovery, polyacrylamide plays a key role in polymer flooding, which increases the amount of oil you can extract from reservoirs. The U.S. market, especially in states like Texas and North Dakota, has seen significant growth in this area.

Industrial Sector | Applications | Consumption Insights |

|---|---|---|

Water Treatment | Growth driven by regulatory compliance and sustainability goals | |

Oil Recovery | Polymer flooding for enhanced oil recovery | 5.1% CAGR in the U.S., especially in shale regions |

Mining | Mineral separation, sludge dewatering | Demand rising due to environmental regulations |

Pulp and Paper | High-BOD effluent treatment, clarification | Modernization and regulatory pressures drive demand |

Civil Engineering | Soil stabilization in tunneling and infrastructure projects | Urban development supports growth |

Textile Manufacturing | Water management and dyeing processes | Focus on sustainability and reduced water use |

Hybrid flocculation systems, which combine polyacrylamide and DADMAC, offer you enhanced efficiency in challenging environments like mining and oil sands. Research shows that adjusting the composition and molecular weight of these polymers can significantly improve flocculation performance. In these systems, polyDADMAC acts as a destabilizer, while polyacrylamide serves as a bridging agent. By optimizing the dosages—typically around 1.2 parts polyDADMAC to 2 parts polyacrylamide—you can achieve near-complete removal of fine particles.

● Hydrophobically modified polyacrylamide copolymers improve flocculation of oil sands tailings.

● The right combination of comonomer composition and molecular weight yields the best results.

● PolyDADMAC and polyacrylamide together achieve optimal flocculation by targeting both charge neutralization and particle bridging.

When you select a polymer for industrial use, you must consider factors such as ionic character, molecular weight, charge density, and water characteristics like pH and temperature. Proper preparation and mixing ensure you get the best results from these advanced materials.

Note: Polyacrylamide stands out for its efficiency, low dosage requirements, and environmental safety. You gain operational savings and improved sustainability compared to traditional chemicals.

You see rapid innovation in biomedical engineering with hydrogels based on polyacrylamide and DADMAC. These materials offer non-toxic, biocompatible, and biodegradable properties. Researchers have developed polyacrylamide nanogels for drug delivery, hydrogel coatings for implanted devices, and composites for targeted cancer therapy. The table below highlights recent advancements:

Advancement | Description |

|---|---|

Polyacrylamide Nanogels | Nanogels for drug delivery with excellent safety profiles. |

Hydrogel Coatings | Coatings that improve biocompatibility of medical implants. |

Biofouling Prevention | Hydrogels that prevent unwanted biological buildup on biosensors. |

Hydrogel Composites | Composites for targeted drug delivery and anticancer activity. |

Hydrogels use a hydrophilic 3D network to load and release drugs. You benefit from their high biocompatibility, mechanical stability, and adhesive properties, especially when polydopamine is added.

You find polyacrylamide in advanced sensors and wearable electronics. Glucose-sensitive hydrogels detect glucose through volume changes. Triple-network hydrogels, which include polyacrylic acid and polypyrrole, can sense human movement. These innovations support the development of smart medical devices and responsive materials.

● Glucose-sensitive hydrogels enable non-invasive monitoring.

● Triple-network hydrogels provide durability and flexibility for wearables.

You rely on these polymers for their flocculation and coagulation abilities. Polyacrylamide interacts with particles through charge density, which changes with pH. DADMAC maintains its charge across a wide pH range, making it effective in diverse conditions. Higher molecular weight DADMAC improves collision efficiency and creates stronger floc structures.

You must consider safety when using these chemicals. Polyacrylamide itself is safe, but trace amounts of acrylamide monomer pose health risks. Regulatory bodies limit monomer content to 0.05% or less. Recent innovations focus on bio-based raw materials and improved manufacturing, reducing energy use and emissions. DADMAC enhances water treatment efficiency, lowering chemical and energy needs, and minimizing environmental impact.

● You see Polyacrylamide and DADMAC driving global water treatment, with the market projected to reach USD 10.0 billion by 2034.

● You benefit from their expanding roles in biomedicine and electronics, where advanced hydrogels and responsive materials are emerging.

Understanding these chemicals helps you make informed decisions in industry and daily life.

You use polyacrylamide mainly as a flocculant. DADMAC acts as a cationic coagulant. Both help you clarify water, but they work through different chemical mechanisms.

You benefit from strict regulations that limit harmful residues. Modern production methods reduce environmental risks. Always follow safety guidelines when handling these chemicals.

Yes, you can combine them in hybrid systems. This approach often gives you better flocculation and particle removal, especially in challenging industrial or municipal water treatment.