Anionic polyacrylamide (APAM) is a high-molecular-weight, water-soluble anionic polymer flocculant used throughout industry to improve solid-liquid separation.

Produced from acrylamide monomers, APAM carries negatively charged functional groups that bind suspended particles, clarifying water and accelerating sludge settling. In water treatment and mining alone, roughly half of all polyacrylamide produced is used for such flocculation and dewatering. For example, EPA data note that 45% of global PAM output is intended for water treatment (coagulation/flocculation and dewatering). APAM complements coagulants like PAC (polyaluminum chloride) to improve efficiency: PAC neutralizes charge while APAM bridges particles into robust flocs.

In global trade, polyacrylamide is classified under acrylic polymers (HS code 3906.xxx). For instance, Chinese customs list polyacrylamide at HS 3906901000. According to Safety Data Sheets, APAM is stable and non-flammable; it dissolves readily in water and has very low toxicity. (The SDS for polyacrylamide generally reports “not hazardous” under normal conditions.) Users should still follow basic precautions: avoid inhaling dust and store APAM in a cool, dry place. (See Anionic polyacrylamide SDS for details on handling, PPE, and first aid.)

Note: Polyacrylamide exists in anionic, cationic, or non-ionic forms. APAM carries negative charges. By contrast, Cationic polyacrylamide (CPAM) carries positive charges and is chosen for different waste streams. This means polyacrylamide can be either anionic or cationic, depending

on its functional groups. (Our blog [What is the difference between anionic and cationic polyacrylamide?])

APAM is widely used to dewater tailings and clarify process water in mining. It causes fine particles in ore and tailings ponds to clump and settle out, improving water reuse and reducing pond volume. For example, APAM “aids in the settling and dewatering of tailings and slurry, contributing to efficient handling of mining wastewater”. Combined with coagulants, APAM flocculation allows rapid thickening of mineral slurries and reduction of turbidity. (For related water treatment coagulants, see our [Polyaluminum Chloride (PAC)].

Textile mills generate colored wastewater containing dyes and colloids. APAM flocculants help aggregate dye molecules and solid impurities, allowing them to be filtered out. Many textile plants dose anionic PAM to improve color removal and reduce biological oxygen demand. (In fact, APAM is listed as suitable for textile effluent treatment in industry guidelines.)

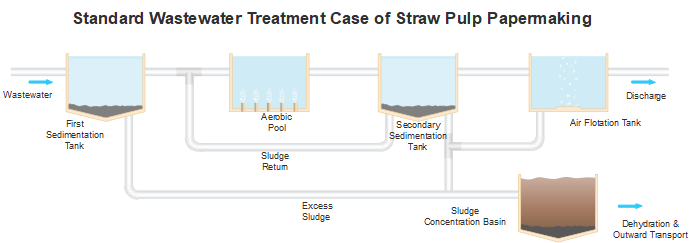

In sewage plants, APAM accelerates solids settling and enhances sludge dewatering. It improves clarification in secondary clarifiers and thickeners, yielding clearer effluent. This reduces treatment times and sludge volume. EPA reports that anionic PAM is a primary coagulant aid in municipal plants, and nearly half of all PAM is used for water/wastewater treatment. By bolstering floc density, APAM lowers residual suspended solids and chemical usage.

APAM is indispensable in the oil and gas industry. Its primary, high-value function here is in enhanced oil recovery (EOR). The high molecular weight polymer increases the viscosity of the injected water, which then sweeps more residual oil out of the reservoir, significantly boosting production. This polymer flooding is one of the most effective EOR techniques available.

APAM is also used in papermaking (to improve fiber retention and drainage), in food/beverage clarification, and even in soil erosion control. Its versatility makes it a staple across industries needing solid-liquid separation, particularly for industrial wastewater and process water streams.

● Superior Flocculation: APAM rapidly binds negatively charged particles, forming large flocs. This greatly enhances sedimentation and filtration, yielding much cleaner water. For example, PAM’s excellent flocculating properties are cited as key to separating solids and liquids in industrial effluents.

● High Efficiency & Cost Savings: Effective APAM grades mean you need less coagulant overall. Tairan’s APAM is noted for “high flocculation efficiency” and cost-effectiveness. By reducing required chemical dosage and speeding up clarification, APAM cuts operational costs. In practice, dosing APAM can significantly lower sludge volumes and minimize chemical use, improving overall efficiency.

● Broad Compatibility: APAM products dissolve quickly in water and work across a wide pH range (often pH 6–12). This means they fit well in diverse water chemistries, from acidic industrial effluent to alkaline mining water. Many grades are also formulated to resist breakdown by chlorine or caustic conditions.

● Safe & Environmentally Friendly: Modern APAMs are essentially non-toxic. Supplier data emphasize that APAM is “safe, non-toxic, hydrolytically stable” and non-flammable. SDS documents confirm that polyacrylamide is not classified as a hazardous substance. Because APAMs do not bioaccumulate or contain harmful impurities, they are generally considered eco-compatible when used properly. (Consult the APAM SDS for disposal guidelines and any regulatory compliance.)

● Enhanced Performance (Synergy with Coagulants): When paired with coagulants like PAC, APAM greatly improves settling. For example, EPA notes that using PAC (charge neutralizer) with APAM “yields high cake solids (>25%) in sludge dewatering”. Such combinations are often used in municipal and industrial wastewater clarifiers to maximize particle removal.

APAM is subject to industrial chemical regulations. Important points:

● Classification: APAM is generally not classified as a dangerous substance under EU and international standards. A typical SDS states “not a hazardous substance” (no signal words). It is not flammable and has very low acute toxicity.

● HS Code: Polyacrylamide is traded under HS chapter 39 (plastics/polymers). In practice, anionic polyacrylamide imports/exports fall under codes like 3906.90. For example, Chinese customs list polyacrylamide as HS 3906901000. Procurement teams should verify the correct code (e.g. 390690 for acrylic polymers) with customs agents.

● Safety Data (SDS): Handle APAM with standard precautions (wear gloves and mask to avoid dust). SDS documents emphasize that APAM is water-soluble and “essentially non-toxic”. In case of fire, combustion yields carbon oxides and nitrogen oxides (CO, CO₂, NOₓ), but APAM itself is not a fuel. There are no special explosion hazards, and it is not classed as a flammable solid. Always follow the manufacturer’s SDS for storage, spill control, and first aid.

● Regulations: APAM must comply with local environmental regulations. In many countries (e.g. under REACH or TSCA), polyacrylamide manufacturers provide MSDS/SDS and documentation of product purity (residual acrylamide monomer $\le$ ppm level). Ensure certificates of analysis are available.

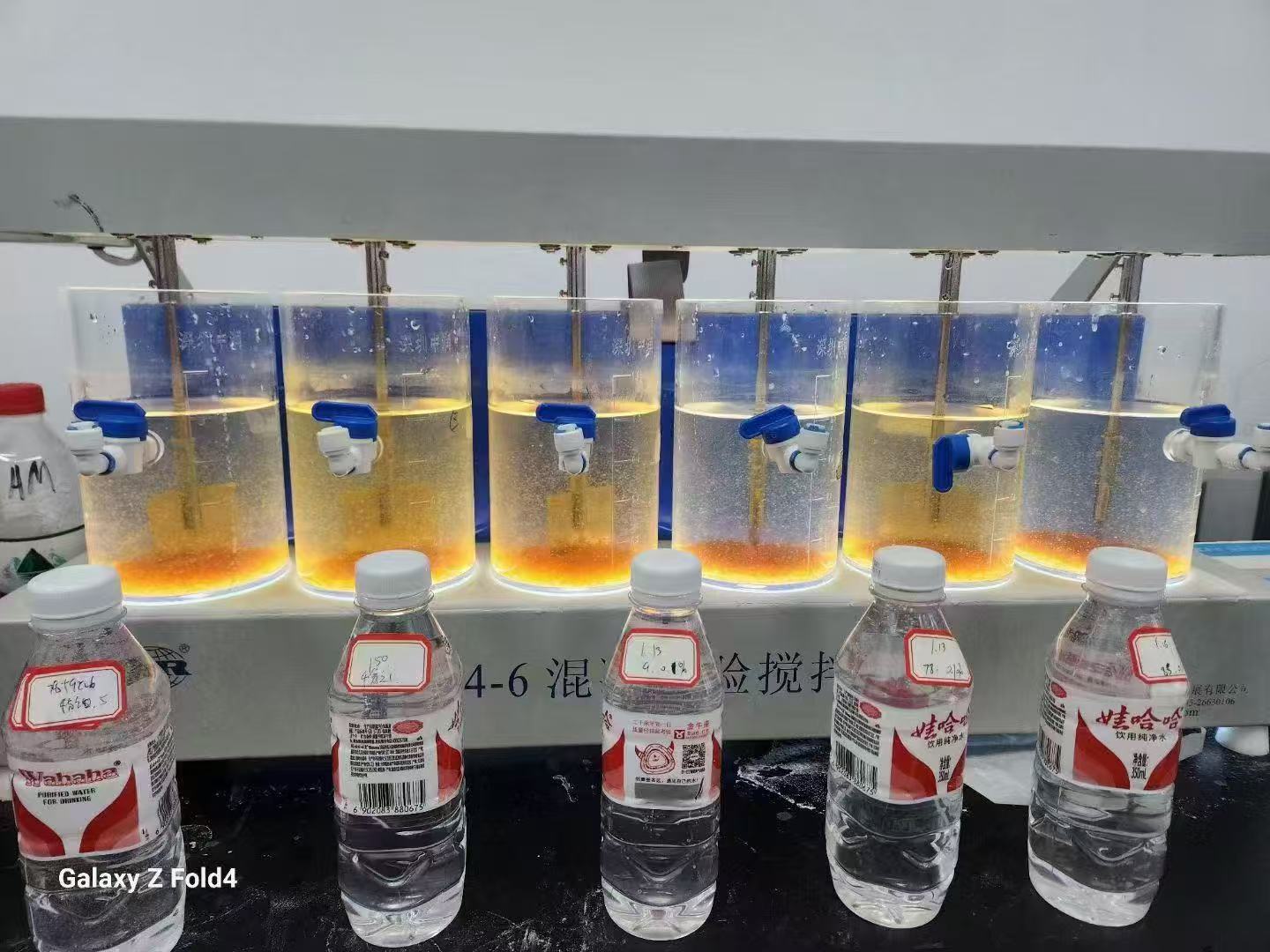

Selecting the optimal APAM grade depends on your application and constraints. Consider these key factors:

1. Charge Density and Molecular Weight: Consult technical sheets – for example, Tairan’s APAM spec sheet shows molecular weights of 8–15 million and pH range 6–12.

2. Application Matching: Match the APAM grade to the media. If treating industrial wastewater with specific contaminants, or if using enhanced oil recovery, you may need specialized grades.

3. Product Form and Dosage: APAM is available in powder or liquid. Powder is more economical to ship, but requires on-site dilution. Check solid content and recommended working concentration.

4. Quality and Compliance: Verify that the APAM meets your purity and safety requirements. Look for SDS availability (“Anionic polyacrylamide SDS” should be provided) and ensure compliance with regulations.

5. Cost Considerations: APAM price varies by region and grade. Bulk buyers should negotiate based on delivery terms and volume.

6. Supplier Support: Choose a supplier that provides technical support. For example, Tairan Chemical offers guidance on various APAM grades on its pages.

Anionic polyacrylamide is a critical component for effective solid-liquid separation across mining, municipal treatment, and the oil and gas industry. By understanding its specific role in flocculation and enhanced oil recovery, procurement managers can ensure optimal performance and cost-efficiency.

For more details or to discuss your specific project needs, please visit our Contact page or explore our APAM range. Let Tairan Chemical be your partner in advanced water and wastewater solutions.

Call to Action:

Request APAM Samples & Technical Support → /contact