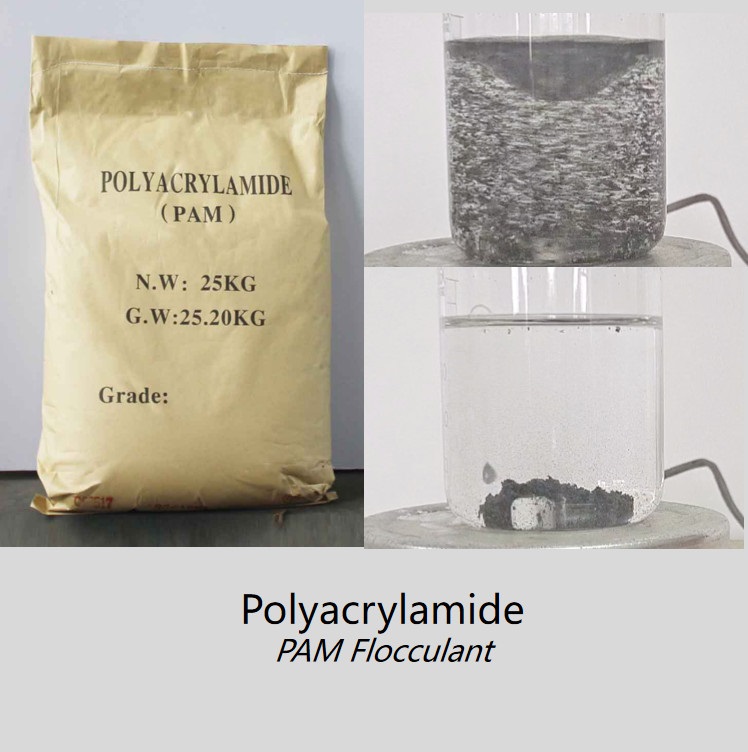

Polyacrylamide (PAM) is a water-soluble, high-molecular-weight polymer made by polymerizing acrylamide monomers. In practice PAM is supplied as a white granular or powder form that dissolves readily in water. Its long linear chain (–CH₂CHCONH₂–) contains many amide groups, giving PAM excellent flocculant and thickening properties. For example, PAM’s chain of amide groups easily binds suspended particles and forms large flocs, making it highly effective for clarifying water and separating solids from liquids. In water treatment and industrial processes, PAM dramatically improves solid-liquid separation, filtration, and turbidity removal. Tairan Chemical’s product line includes a range of polyacrylamide (PAM) products in powder form for fast on-site dissolution.

Polyacrylamide is generally a linear-chain polymer of the formula (C₃H₅NO)ₙ. It is often referred to simply as an acrylamide polymer; in many for.mulations it is copolymerized with small amounts of other monomers (for example, acrylic acid) to adjust its charge. In its pure form it is nonionic, but PAM is produced commercially in three ionic grades (charge types):

Anionic PAM (APAM): carries negative charges (often via partial hydrolysis or copolymerization with sodium acrylate). Anionic PAM (anionic flocculant) is used wherever suspended solids and organic colloids are negatively chargedtairanchemical.comtairanchemical.com.

Cationic PAM (CPAM): carries positive charges (via incorporation of cationic monomers). It attracts negatively charged contaminants like oils and organicstairanchemical.comtairanchemical.com.

Nonionic PAM (NPAM): has virtually no net charge. It is stable across pH extremes and useful when charge interactions must be minimizedtairanchemical.comnature.com.

Each form is produced as an ionic polymer flocculant tailored to specific applications.(Learn more about APAM and CPAM in Tairan’s blog on [anionic vs. cationic polyacrylamide].)

Wastewater Treatment (Municipal & Industrial): PAM is a primary flocculant for wastewater plants. In sewage and effluent treatment, APAM and CPAM accelerate sludge settling and improve clarifier performance. By aggregating fine solids into dense flocs, PAM yields clearer effluent and greatly enhances sedimentation. In fact, the U.S. EPA reports that roughly 45% of the world’s PAM output is used in water/coagulation-flocculation and sludge dewatering.

Oil & Gas (Enhanced Oil Recovery): High-molecular-weight PAM boosts water viscosity in EOR (polymers flood) to improve oil displacement. Both nonionic and cationic PAM grades are used in injection fluids. PAM also finds use in treating oilfield produced water, helping remove suspended oil and solids.

Sludge Dewatering and Thickening: PAM dramatically improves the efficiency of sludge dewatering units. Strong floc formation leads to rapid water release, producing dense filter cakes. Industries use PAM to reduce sludge volume and disposal costs while recovering more water from slurries.

Mining & Mineral Processing: PAM is widely used in tailings ponds and mineral processing plants. Anionic PAM causes fine ore particles to clump and settle, improving tailings dewatering and water reuse. Rapid flocculation of suspended solids reduces turbidity in process water.

Pulp, Paper & Textiles: In papermaking, PAM (especially cationic grades) is added to improve fiber retention, drainage and sheet strength. In textile dye wastewater, APAM aids in aggregating dyes and colloids so they can be filtered out.

Agriculture and Soil Stabilization: Nonionic PAM is used as a soil conditioner and erosion-control agent. It binds clay particles and stabilizes soils, reducing runoff and sealing.

Tairan Chemical’s PAM products are engineered for these sectors – see our [Anionic Polyacrylamide (APAM) flocculant page], [Cationic PAM page], and [Non-Ionic PAM page]for details on grades and specs.

Choosing the right PAM grade depends on the application:

Charge Type: Anionic PAM (APAM) is best for treating negatively charged waste (e.g. municipal effluent, mining tailings). Cationic PAM (CPAM) is ideal when flocculating acidic or negatively charged organic waste (such as textile or oilfield effluent). Nonionic PAM works in high-pH or variable-pH conditions where neither charge is wanted.

Molecular Weight (MW): Higher-MW PAM (tens of millions Daltons) creates larger, stronger flocs – useful for sludge dewatering and clarifying high-turbidity water. Lower-MW PAM is often used as a retention aid. (Tairan’s PAM powders come in MW ranges from about 5–20 million Daltons.)

Formulation: PAM is typically supplied as a dry powder, which is economical to ship and store. Powder PAM dissolves in water under agitation to form a 0.1–0.5% working solution. Specialty liquid or emulsion forms are also available for precise dosing.

Quality Factors: Look for PAM with high purity and controlled hydrolysis. A good polymer has low residual monomer (acrylamide) and consistent charge density. Tairan’s PAM meets industry standards for solid content (≥88%) and particle size for rapid dissolution.

For more guidance, see Tairan Chemical’s blog posts – e.g. “Introduction to Anionic Polyacrylamide”and “Anionic vs. Cationic Polyacrylamide”– which discuss how to match PAM types to different effluents. In general, start by testing a range of polymer doses and grades to optimize floc strength and settling rate for your specific water chemistry.

Polyacrylamide is a commodity chemical produced globally. According to market studies, China dominates PAM production (over 50% of demand),with SNF Floerger, BASF, Kemira and major Chinese firms among the top manufacturers. As a key supplier, Tairan Chemical manufactures and distributes industrial-grade PAM and flocculants. We adhere to strict quality control so that customers worldwide receive consistent, high-performing polymers. If you are looking to buy polyacrylamide, Tairan’s portfolio covers anionic, cationic, and nonionic grades in bulk powder form.

Polyacrylamide (PAM) is a versatile copolymer (high-molecular-weight polymer) widely used as a flocculant in water treatment, mining, oil recovery, and other industrial processes. Different forms (anionic, cationic, nonionic) are tailored to specific charge and pH conditions. The right grade (charge density, molecular weight, form) depends on your application’s solids content, pH, and treatment goals. In every case, PAM significantly improves solid-liquid separation and process efficiency.

Buy Polyacrylamide from Tairan Chemical: For technical support or quotations, contact Tairan Chemical’s sales team. We offer high-quality PAM in bulk, with customizable grades and competitive pricing. Contact us now through our [Contact Us page] to discuss your water treatment or process needs – our experts will help you select the optimal PAM grade and arrange prompt delivery.