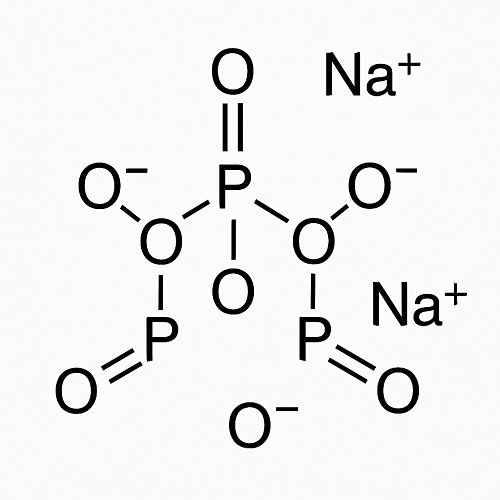

Understanding sodium tripolyphosphate (STPP) is crucial for professionals interested in food safety, industrial processes, and effective cleaning solutions. This compound, known by its chemical formula Na5P3O10, is a multifaceted ingredient used across various industries globally. Let's delve into the essential facts about this versatile chemical, its uses, and its benefits.

Sodium Tripolyphosphate is a sodium salt of triphosphoric acid. It appears as a white, water-soluble powder and is a common, cost-effective ingredient in both industrial-grade and food-grade products. Due to its superior versatility and effectiveness, bulk STPP is a highly sought-after chemical used extensively in food processing, cleaning products, and water treatment.

The primary strength of STPP lies in its ability to act as a powerful sequestering agent (or chelating agent).

● Water Softening: STPP effectively binds with hard water ions like calcium (Ca2+) and magnesium (Mg2+). By sequestering these ions, it prevents them from interfering with detergents or forming mineral scale, significantly enhancing the efficiency of industrial processes.

● Dispersing Agent: Its dispersive power helps maintain tiny particles (like clay, pigment, or food solids) uniformly suspended in water. This is vital in processes like ceramic slip preparation and textile dyeing.

In the food industry, Food Grade Sodium Tripolyphosphate is primarily used as an additive to enhance texture and moisture retention.

● Moisture Retention: It acts as an emulsifier and helps to maintain the quality of seafood, poultry, and meat products. By binding water molecules within the protein structure, STPP prevents the loss of moisture during cooking and freezing, resulting in juicier and more tender products, which is a key advantage for processed meats.

● Preservation: Additionally, STPP aids in the preservation of color and flavor and can improve the shelf life of processed foods by inhibiting the growth of certain bacteria and fungi.

Beyond the realm of food, Industrial Grade STPP plays a significant role in various large-scale applications:

It is a key component in cleaning products, particularly laundry and dishwashing detergents. As a detergent builder, STPP acts as a water softener by binding Ca2+ and Mg2+ ions, which dramatically enhances the cleaning power and efficiency of surfactants in both household and industrial cleaning solutions.

In water treatment processes, bulk Sodium Tripolyphosphate helps prevent the formation of scale and corrosion, ensuring the efficient operation of machinery and plumbing systems. It is also used in ceramics manufacturing, textile production, and as a powerful dispersing agent in paints and coatings.

While STPP is generally recognized as safe (GRAS) by bodies like the FDA when used appropriately within set limits, it is important to note that regulatory bodies globally have established limits on its use, especially in food products, to ensure consumer safety. Most reputable STPP suppliers provide technical data (like Material Safety Data Sheets / MSDS) detailing usage guidelines and purity levels.

While Sodium Tripolyphosphate (STPP) is a powerhouse in the polyphosphate family, buyers and engineers often compare it with other vital phosphates based on application needs. Understanding these differences can help professionals select the right product for specific requirements:

● STPP vs. Sodium Hexametaphosphate (SHMP): Both are excellent sequestrants, but SHMP (Na6P6O18) generally exhibits a higher sequestering capacity in certain water treatment and metal ion binding applications, especially for highly demanding industrial processes. If your primary need is robust anti-scaling and dispersion over a wide temperature range, you may need to learn more about [Sodium Hexametaphosphate (SHMP) technical specifications] here.

● STPP vs. Tetrasodium Pyrophosphate (TSPP): TSPP (Na4P2O7) is often used in oil drilling and as a deflocculant in specific ceramic formulations. While STPP is the preferred bulk builder for detergents, TSPP sometimes provides better stabilization in certain processed cheese and dairy applications. Explore the full range of uses for [Tetrasodium Pyrophosphate (TSPP)] here.

For bulk purchasers of cleaning agents and food stabilizers, STPP often remains the most cost-effective and versatile choice due to its balanced properties.

Sodium Tripolyphosphate remains an indispensable compound, underpinning the effectiveness of modern cleaning agents and contributing significantly to global food quality. Its balanced properties—high solubility, excellent chelating ability, and strong dispersive power—ensure its continued relevance across industrial and consumer sectors worldwide.