Flocculants play a pivotal role in modern wastewater treatment, directly impacting both the operational efficiency of treatment plants and the quality of treated effluent. An optimally designed flocculant dosing system ensures that the right amount of polymer is added at the right time, maximizing floc formation while minimizing chemical consumption. TAIRAN CHEMICAL specializes in advanced flocculant dosing solutions that improve treatment outcomes, reduce costs, and support sustainable water management.

The effectiveness of wastewater treatment heavily depends on accurate dosing of polymers such as polyacrylamide (PAM). Overdosing leads to unnecessary chemical expenses, increased sludge volume, and potential downstream operational challenges. Underdosing, on the other hand, results in incomplete flocculation, poor settling, and higher turbidity in treated water. By optimizing dosing systems, wastewater plants can achieve:

Consistent removal of suspended solids

Improved sludge dewatering efficiency

Reduced chemical usage and operational costs

Compliance with environmental discharge standards

The best flocculant dosing system balances these factors to ensure both economic and environmental efficiency.

An effective flocculant dosing system should consider the following design principles:

Accurate Chemical Measurement

Use precision metering pumps or gravimetric dosing devices to control polymer addition accurately according to flow rates and water characteristics.

Proper Solution Preparation

Polymer solutions should be prepared at the recommended concentration (typically 0.1–0.5% for high-molecular-weight PAM) to ensure complete dissolution and optimal chain extension for maximum flocculation.

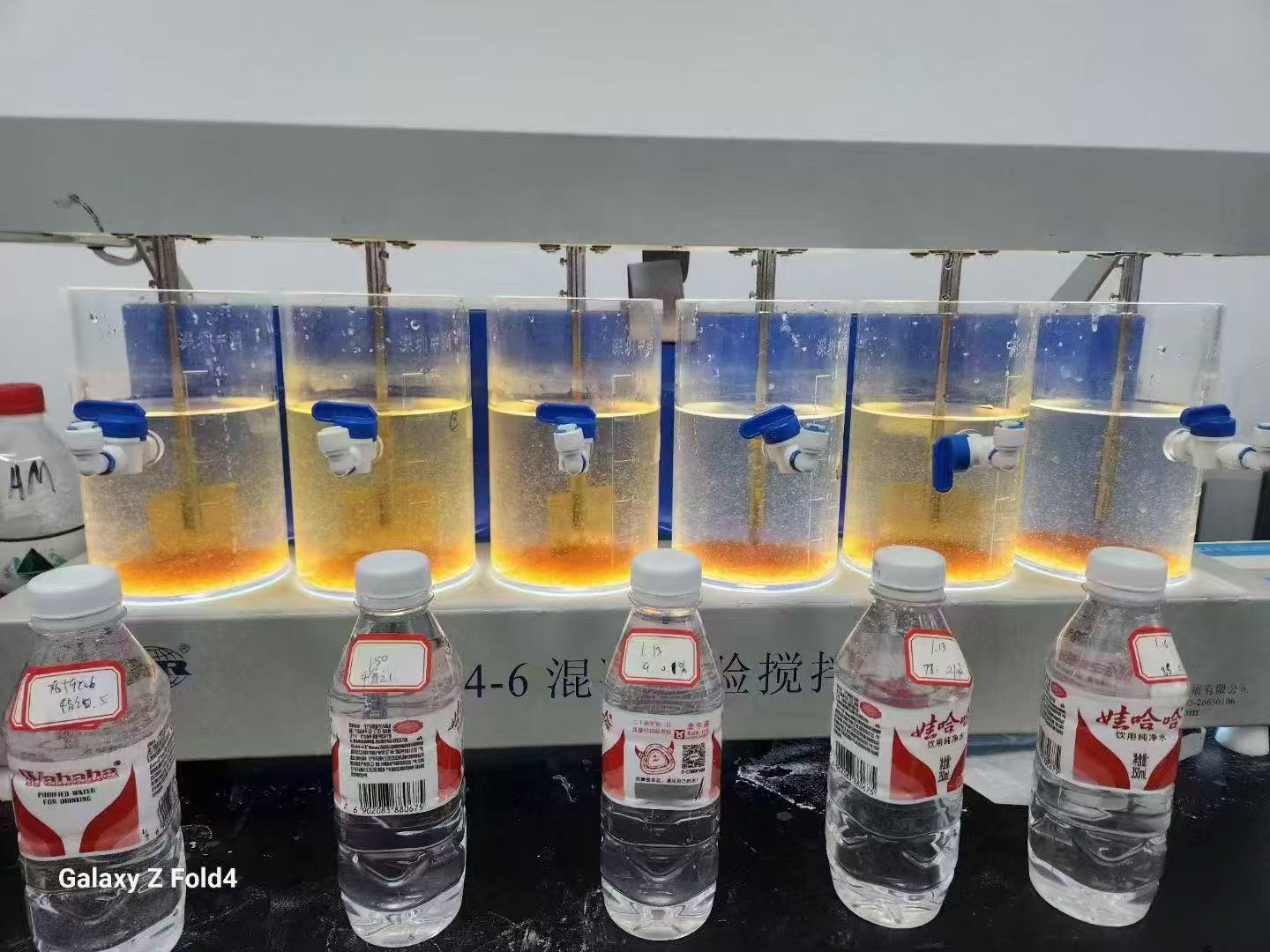

Optimized Mixing and Contact

Adequate initial rapid mixing disperses the polymer uniformly, followed by gentle flocculation zones to allow floc growth without shearing.

Strategic Dosing Points

Multiple dosing points can enhance collision and floc formation, while single-point dosing can be suitable for simple flow systems. Pre-treatment, biological treatment, and post-treatment stages may each require specific dosing strategies.

Automation and Monitoring

Integrating flow sensors, turbidity meters, and feedback controls ensures real-time adjustments, maintaining consistent water quality while minimizing chemical consumption.

TAIRAN CHEMICAL provides a comprehensive portfolio of flocculants and dosing equipment, designed to meet diverse wastewater treatment needs:

High-performance Anionic and Cationic PAM

Suitable for industrial wastewater, municipal water, and sludge dewatering.

Liquid and Solid Polymer Options

Flexible dosing strategies reduce labor, improve safety, and minimize storage space.

Automated Dosing Systems

Integrated solution preparation, mixing, and metering optimize chemical efficiency.

Durable, Corrosion-Resistant Components

Ensures long-term operation in harsh chemical environments.

By choosing TAIRAN CHEMICAL’s solutions, wastewater plants can reduce chemical usage by up to 30% while maintaining or improving treatment performance.

TAIRAN CHEMICAL flocculant dosing systems are widely applied across multiple sectors:

Municipal Wastewater Treatment – Enhances effluent clarity and reduces sludge handling costs

Industrial Wastewater – Mining, paper, textile, and chemical industries benefit from improved solids removal

Sludge Dewatering – Improves centrifuge and belt press efficiency, reducing disposal volume

Water Reuse & Recycling – Supports advanced treatment for irrigation or industrial reuse

Accurate flocculant dosing is not only technically essential but also economically advantageous. By adopting TAIRAN CHEMICAL’s optimized dosing systems, plants achieve:

Lower polymer consumption without compromising treatment quality

Reduced energy and labor costs associated with sludge handling

Minimized risk of pipe clogging and uneven polymer distribution

Enhanced operational stability and predictable treatment outcomes

When selecting a flocculant dosing system, consider the following factors:

Water Quality Parameters – pH, turbidity, total suspended solids, and temperature

Plant Flow and Volume – Daily water volume and peak flow conditions

System Automation Needs – Level of monitoring and feedback control required

Chemical Type – Solid vs. liquid polymer, anionic vs. cationic PAM

Space and Installation Constraints – Compact systems with integrated mixing and storage optimize footprint

TAIRAN CHEMICAL offers expert consultation to customize dosing systems tailored to your plant’s specific requirements.

Efficient flocculant dosing is a cornerstone of successful wastewater treatment. A well-designed system maximizes polymer efficiency, reduces operational costs, and ensures compliance with environmental standards. TAIRAN CHEMICAL’s best-in-class flocculant dosing solutions provide reliable performance, automation, and flexibility for industrial and municipal wastewater applications.

Optimize your wastewater treatment process today – contact TAIRAN CHEMICAL for a tailored dosing system solution.