Polyacrylamide (PAM) serves as a crucial raw material across multiple industries, particularly excelling in municipal water treatment and industrial wastewater treatment. These synthetic polymers come in three main types—cationic (positive charge), anionic (negative charge), and nonionic (neutral)—each designed for specific applications in the PAM in water treatment process.

Anionic polymers feature negatively charged functional groups along their polymer chain, created through anionic polymerization. This process produces high molecular weight anionic polymers ideal for capturing positively charged particles.

● Drinking water treatment: Removes suspended solids and turbidity

● Coal washing operations: Separates coal from impurities

● Municipal water treatment plants: Clarifies raw water sources

● Mining industry: Settles mineral processing wastewater

Cationic polymerization creates polymers with positive charges, making them perfect for industrial wastewater treatment containing organic matter. The cationic polymerization process yields medium to high molecular weight polymers that excel in sludge dewatering.

● Industrial wastewater treatment for organic contaminant removal

● Municipal water treatment sludge dewatering

● Paper mill wastewater clarification

● Food processing wastewater treatment

Nonionic PAM operates without electrical charge, functioning through hydrogen bonding and molecular entanglement. This makes it exceptionally effective in challenging water conditions where ionic polymers might struggle.

● High salinity wastewater streams

● Variable pH conditions in industrial wastewater treatment

● Temperature fluctuations in process water

● Systems with dissolved solids interference

The choice between cationic vs anionic polymer depends primarily on the target particles' charge. Cationic vs anionic polymer performance varies significantly based on water chemistry and contaminant characteristics.

● Anionic polymers typically feature higher molecular weights

● Cationic polymers offer stronger charge densities

● Nonionic PAM provides molecular flexibility

In drinking water treatment, anionic polymers prove most effective for removing inorganic suspended solids. The selection between cationic vs anionic polymer in PAM in water treatment depends on source water characteristics.

For industrial wastewater treatment, the cationic vs anionic polymer decision becomes critical. Cationic polymers typically handle organic-rich wastewaters, while anionic polymers work better with inorganic suspensions.

Municipal water treatment facilities often employ both anionic polymers for primary clarification and cationic polymers for sludge processing, demonstrating the importance of understanding cationic vs anionic polymer characteristics.

● pH levels and alkalinity

● Total dissolved solids

● Temperature variations

● Contaminant types and concentrations

● Clarification speed needed

● Sludge dewatering requirements

● Final water quality standards

● System retention times

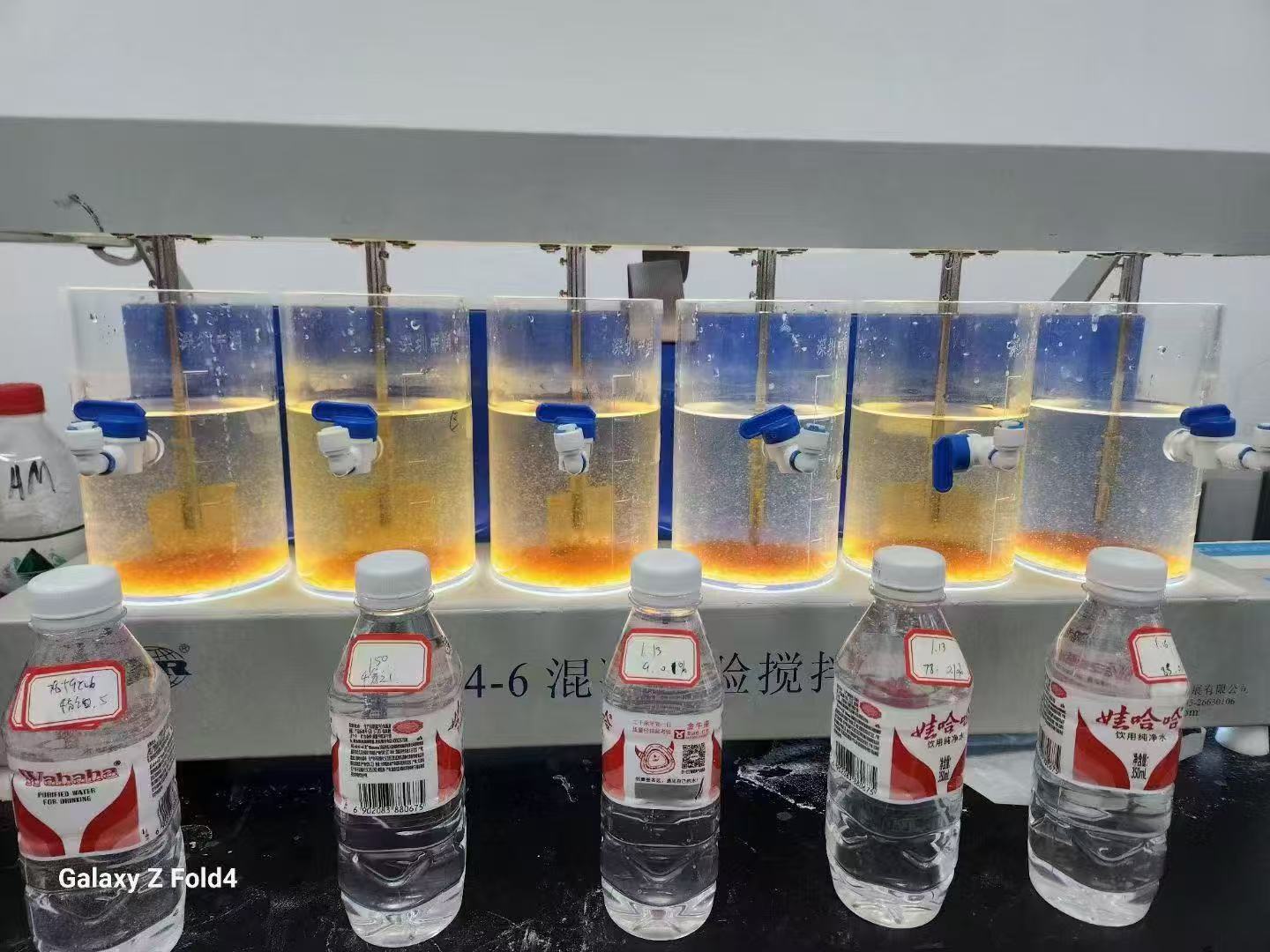

Proper dosing of PAM in water treatment ensures cost-effective operation while meeting treatment objectives. Both under-dosing and over-dosing can compromise treatment efficiency in municipal water treatment and industrial wastewater treatment applications.

● Ensure proper polymer hydration

● Optimize mixing energy input

● Monitor floc formation visually

● Adjust based on settling characteristics

All PAM products used in drinking water treatment must meet relevant safety standards and regulatory requirements. Proper handling and application ensure environmental protection while achieving water treatment goals.

Understanding the differences between cationic, anionic, and nonionic PAM types enables water treatment professionals to select the most effective raw material for their specific needs. Whether addressing drinking water treatment, municipal water treatment, or challenging industrial wastewater treatment scenarios, the proper selection and application of PAM in water treatment processes ensures optimal performance and cost efficiency.

The decision between cationic vs anionic polymer applications ultimately depends on comprehensive water characterization and treatment objectives. By considering all factors—from water chemistry to process requirements—operators can maximize the benefits of these versatile polymers in their water treatment operations.