As global water scarcity intensifies and industrial pollution grows, the importance of effective treatment of wastewater has never been greater. According to the 2023 UNESCO World Water Report, over 80% of wastewater globally is discharged untreated. This poses significant environmental and public health risks.

Among the various methods—physical, biological, and chemical—chemical treatment plays a crucial role. It is essential for improving the quality of effluent and handling complex contaminants that other methods miss.

This article explores essential wastewater chemicals, their types, applications, and selection methods. We'll also explain the differences between wastewater treatment chemicals, water treatment chemicals, and WWTP chemicals—terms often used interchangeably but with distinct meanings in practice.

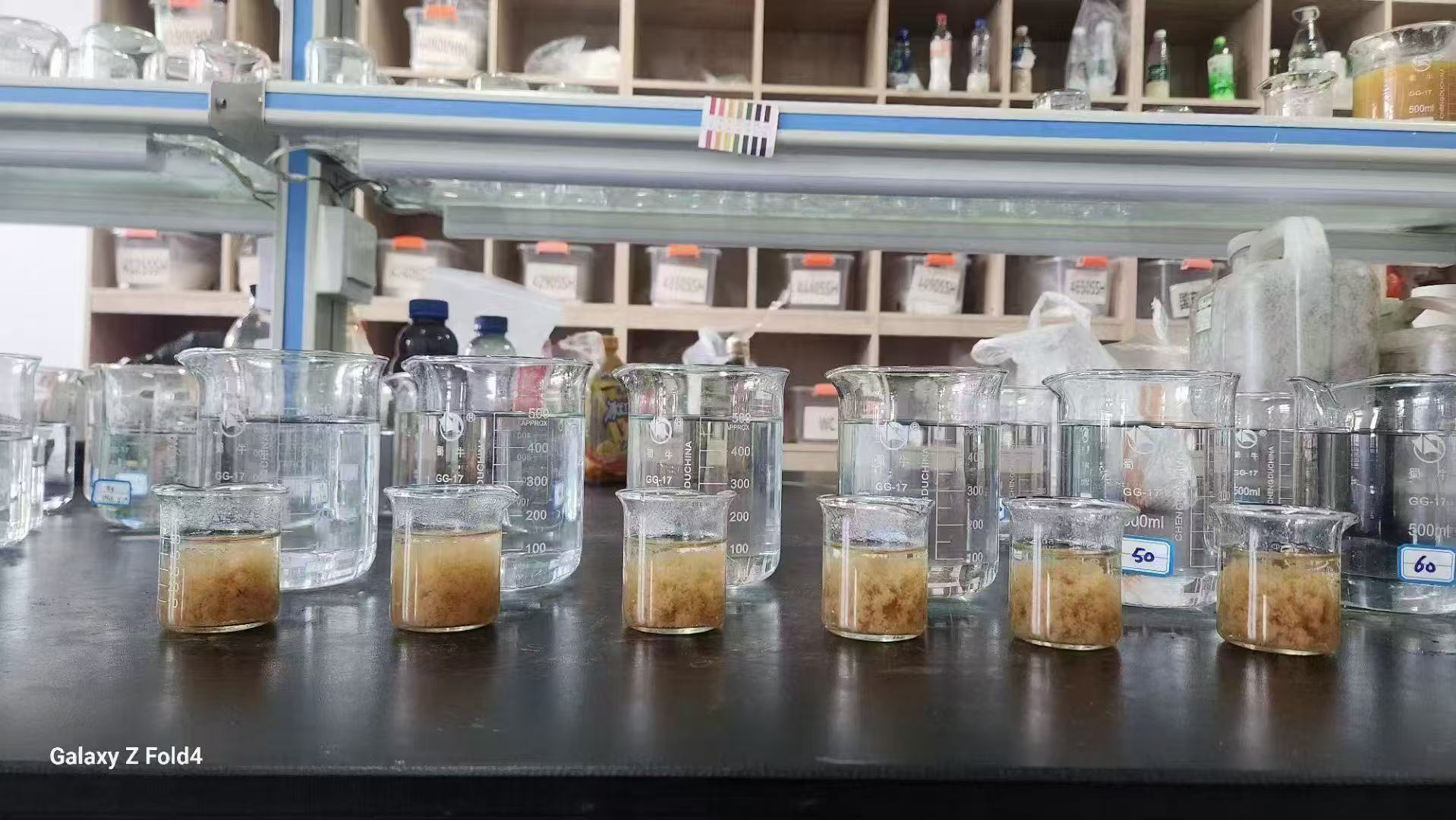

These are the workhorses of chemical wastewater treatment, designed to separate solids from liquid.

| Chemical Type | Purpose | Examples |

| Coagulants | Neutralize the charge on suspended particles, allowing them to aggregate. | Inorganic: Aluminum Sulfate (Alum), Poly Aluminium Chloride (PAC ). Organic: PolyDADMAC (strong cationic properties). |

| Flocculants | Facilitate the formation of larger, heavy flocs from destabilized particles via bridging. | Synthetic: Polyacrylamide (PAM) (Anionic, Cationic, Non-Ionic). Natural: Chitosan (biodegradable). |

Maintaining the correct pH level is non-negotiable, as most chemicals only work within an optimal range (e.g., pH 6.5-7.5).

● Acids (to Lower pH): Sulfuric acid, hydrochloric acid.

● Bases (to Raise pH): Lime, sodium hydroxide (for optimal chemical activity and metal precipitation).

Used typically in the final stage of the treatment process to ensure safety before discharge or reuse.

● Chlorine and Sodium Hypochlorite (common in municipal WWTP chemicals).

● Ozone, UV, and Chlorine Dioxide (advanced solutions).

These additives handle specific contaminants and operational issues:

● Phosphorus Removal Agents: Ferric chloride, alum, or lanthanum-based agents.

● Heavy Metal Precipitants: Chelating agents for common industrial contaminants (lead, mercury, chromium, etc.).

● Defoamers: Silicone or non-silicone-based, crucial for suppressing foaming in aeration tanks.

Municipal WWTPs often use coagulants and flocculants in primary and secondary stages to remove suspended solids, reduce BOD/COD, and prepare water for biological treatment of wastewater. Disinfectants are used post-filtration to ensure safety before discharge.

Example: A city plant reduced PAC consumption by 25% using customized polymer blends, successfully cutting sludge disposal costs significantly.

Industries face complex effluent profiles requiring tailored chemical strategies to improve the quality of discharge:

● Pulp & Paper: Alum and cationic PAM to remove lignin and fiber.

● Electroplating: Sodium hydroxide for pH level control and chelators for heavy metal removal.

● Food Processing: Coagulation-flocculation to handle high oil and grease content.

In tailings management, flocculants are vital for separating solids and reclaiming process water. In oilfields, demulsifiers and non-ionic polymers break down oil-water emulsions effectively.

1. Choosing the right chemical requires a scientific approach, focusing on multiple factors:

Water Quality Assessment: Key parameters include TSS, COD, BOD, pH level, turbidity, and ionic strength. Methods like Jar testing and zeta potential analysis are crucial.

2. Process Compatibility: Focus on coagulants and flocculants for Primary Treatment; emphasize disinfection for Tertiary Treatment. Always consider downstream impacts like sludge volume.

3. Economic Considerations: Analyze cost per unit treatment (e.g., $/kg of contaminant removed), balancing the dosing rate, removal efficiency, and sludge handling costs.

4. Regulatory Compliance: Ensure chemical use aligns with local discharge permit limits and international standards, such as EPA and REACH chemical restrictions .

The effective use of wastewater chemicals is critical for regulatory compliance, environmental protection, and operational efficiency. The right combination of coagulants, flocculants, and specialty additives can dramatically improve the quality of effluent and reduce long-term costs in the overall treatment process.

Whether you're a plant operator or environmental engineer, understanding and optimizing your wastewater chemicals strategy is essential. Partnering with a trusted supplier ensures access to high-purity, customized solutions designed for your specific needs.

Need high-performance PAC or PAM for your wastewater treatment?Contact Tairan Chemical Today.