Quick Summary: Polymer flocculants are high-molecular-weight compounds essential for modern water treatment systems. These versatile chemicals enable efficient solid-liquid separation, reduce operational costs, and improve water quality across municipal and industrial applications. This comprehensive guide explores polymer flocculant types, mechanisms, applications, and selection criteria for optimal treatment performance.

What is a Polymer Flocculant?

Polymer flocculants are water-soluble macromolecules designed to aggregate suspended particles in water and wastewater treatment processes. Unlike traditional coagulants, polymer flocculants work through bridging mechanisms and charge neutralization, creating larger, more stable flocs that settle rapidly and can be easily separated from treated water.

The molecular structure of polymer flocculants typically consists of long chains with molecular weights ranging from hundreds of thousands to several million Daltons. This unique structure enables polymer flocculants to bridge multiple particles simultaneously, forming strong aggregates that withstand shear forces during treatment processes.

Types of Polymer Flocculants

1. Anionic Polymer Flocculants

Anionic polymer flocculants carry negative charges along their molecular chains. These polymer flocculants are particularly effective in treating positively charged particles commonly found in mineral processing, coal washing, and certain industrial wastewater streams. Anionic polyacrylamide (APAM) represents the most widely used anionic polymer flocculant, offering excellent performance in applications requiring high molecular weight and controlled charge density.

2. Cationic Polymer Flocculants

Cationic polymer flocculants possess positive charges, making them ideal for treating negatively charged colloids prevalent in municipal wastewater, organic sludge, and biological treatment systems. These cationic polymer flocculants demonstrate superior performance in sludge dewatering applications, often reducing polymer consumption by 30-50% compared to traditional treatment methods.

3. Nonionic Polymer Flocculants

Nonionic polymer flocculants operate primarily through hydrogen bonding and van der Waals forces. While less common than their charged counterparts, nonionic polymer flocculants excel in specific applications where pH fluctuations or high salinity would compromise the effectiveness of ionic polymers.

4. Amphoteric Polymer Flocculants

Amphoteric polymer flocculants contain both positive and negative charges within the same molecule. This dual functionality allows these polymer flocculants to adapt to varying water conditions, making them versatile solutions for complex treatment scenarios.

How Polymer Flocculants Work: Mechanisms and Principles

The effectiveness of polymer flocculants relies on several fundamental mechanisms that work synergistically to achieve optimal particle aggregation. Understanding these mechanisms is crucial for proper water treatment system design:

Charge Neutralization: Polymer flocculants neutralize surface charges on suspended particles, reducing electrostatic repulsion

Bridging: Long polymer chains attach to multiple particles, creating physical bridges between them

Patch Flocculation: Polymer molecules create localized charge patches that attract oppositely charged particle regions

Sweep Flocculation: Polymer flocculants enmesh particles within precipitated polymer networks

Key Applications of Polymer Flocculants

| Industry | Application | Preferred Polymer Type | Key Benefits |

|---|---|---|---|

| Municipal Water Treatment | Primary clarification, sludge thickening | Cationic polymer flocculant | Reduced sludge volume, improved clarity |

| Mining & Minerals | Tailings treatment, ore processing | Anionic polymer flocculant | Faster settling, water recovery |

| Oil & Gas | Produced water treatment, drilling mud | Cationic/Anionic polymer flocculant | Enhanced oil recovery, reduced disposal costs |

| Paper & Pulp | Retention aid, wastewater treatment | Cationic polymer flocculant | Improved fiber retention, cleaner effluent |

| Food & Beverage | Process water treatment, waste management | Food-grade polymer flocculant | Regulatory compliance, water reuse |

Benefits of Using Polymer Flocculants

Cost Efficiency

Polymer flocculants typically require lower dosages than traditional coagulants, reducing chemical costs by 20-40% while achieving superior treatment results.

Enhanced Performance

Faster settling rates and stronger floc formation lead to increased treatment capacity and improved water quality parameters.

Reduced Sludge Volume

Polymer flocculants produce denser, more compact sludge, reducing disposal costs and environmental impact.

pH Flexibility

Many polymer flocculants maintain effectiveness across wide pH ranges, eliminating the need for pH adjustment chemicals.

Equipment Protection

Non-corrosive nature of polymer flocculants extends equipment life and reduces maintenance requirements.

Environmental Safety

Modern polymer flocculants are designed for biodegradability and minimal environmental impact when properly applied.

Selecting the Right Polymer Flocculant

Choosing the optimal polymer flocculant for your application requires careful consideration of multiple factors. Water chemistry, particle characteristics, and treatment objectives all influence polymer selection and performance. Our jar testing services can help determine the best polymer for your specific needs.

Key Selection Criteria:

1. Particle Charge and Size Distribution: Understanding the zeta potential and particle size distribution of your suspended solids guides the selection between anionic, cationic, or nonionic polymer flocculants. According to the EPA's water treatment guidelines, laboratory jar testing remains the gold standard for determining optimal polymer type and charge density.

2. Water Chemistry Parameters: pH, alkalinity, hardness, and ionic strength significantly impact polymer flocculant performance. High salinity environments may require specialized polymer formulations designed to maintain effectiveness under challenging conditions.

3. Treatment Objectives: Whether prioritizing turbidity removal, sludge dewatering, or specific contaminant reduction influences polymer selection. Different molecular weights and charge densities optimize performance for distinct treatment goals.

4. Regulatory Requirements: Ensure selected polymer flocculants meet relevant regulatory standards for your application, particularly in drinking water treatment or food processing applications where NSF certification may be required.

Dosing and Application Best Practices

Proper polymer flocculant application is critical for achieving optimal treatment performance while minimizing chemical consumption. Effective polymer programs require attention to preparation, dosing, and mixing conditions. Our technical support team provides comprehensive guidance on polymer application best practices.

Maintain polymer solution concentrations between 0.1-0.5% for optimal performance

Use appropriate mixing energy to achieve complete polymer dissolution without chain degradation

Age polymer solutions for recommended time before use (typically 30-60 minutes)

Prepare fresh polymer solutions daily to maintain maximum activity

Dosing optimization through jar testing establishes baseline polymer requirements, but continuous monitoring and adjustment ensure sustained performance as water conditions change. Advanced polymer feed systems with automated control capabilities can maintain optimal dosing while reducing operator intervention.

Innovations in Polymer Flocculant Technology

The polymer flocculant industry continues evolving with innovations addressing environmental concerns and performance enhancement. Bio-based polymer flocculants derived from renewable resources offer sustainable alternatives to traditional synthetic polymers while maintaining comparable performance.

Smart polymer systems incorporating responsive functionalities adapt to changing water conditions automatically, optimizing treatment without manual intervention. These advanced polymer flocculants represent the future of intelligent water treatment systems, as discussed in recent research from the American Water Works Association.

Hybrid polymer-coagulant formulations combine the benefits of both treatment approaches, offering enhanced performance in challenging applications. Our hybrid chemical solutions simplify chemical programs while improving overall treatment efficiency.

Environmental Considerations and Sustainability

Modern polymer flocculant development prioritizes environmental compatibility alongside performance. Biodegradable polymer flocculants break down naturally after use, minimizing long-term environmental impact. Manufacturers increasingly focus on reducing acrylamide content and developing safer polymer alternatives.

Life cycle assessments demonstrate that polymer flocculants often provide environmental benefits through reduced chemical consumption, lower sludge volumes, and decreased energy requirements compared to traditional treatment methods. The World Health Organization's water treatment guidelines emphasize the importance of sustainable treatment practices. Proper polymer selection and application maximize these sustainability advantages.

Troubleshooting Common Polymer Flocculant Challenges

Even well-designed polymer programs occasionally encounter performance issues. Understanding common challenges and their solutions ensures consistent treatment success. Our troubleshooting guide provides detailed solutions for common polymer application problems:

Poor Floc Formation: Inadequate mixing, incorrect polymer type, or suboptimal dosing often cause weak floc formation. Reviewing mixing conditions and conducting fresh jar tests typically identifies corrective actions.

Polymer Overdosing: Excessive polymer consumption may indicate changed water conditions or degraded polymer quality. Regular polymer activity testing and dose optimization prevent wasteful overdosing.

Seasonal Variations: Temperature changes and seasonal water quality variations require polymer program adjustments. Proactive monitoring and flexible dosing strategies maintain performance throughout the year.

The Future of Polymer Flocculants in Water Treatment

As water scarcity intensifies globally and regulatory requirements strengthen, polymer flocculants will play increasingly critical roles in water treatment and resource recovery. Advanced polymer technologies enabling selective contaminant removal, enhanced biodegradability, and improved sustainability will drive industry adoption.

Integration with digital water management systems allows real-time polymer optimization based on continuous water quality monitoring. Machine learning algorithms predict optimal polymer dosing, reducing chemical consumption while maintaining treatment objectives. Research from leading institutions like Stanford's Water Center continues to advance our understanding of polymer applications.

The development of multifunctional polymer flocculants combining flocculation with additional treatment capabilities, such as heavy metal chelation or pathogen inactivation, represents exciting advancement opportunities in water treatment technology.

Partner with Tairan Chemical for Your Polymer Flocculant Needs

Selecting and implementing the right polymer flocculant program requires expertise, quality products, and reliable technical support. Tairan Chemical offers comprehensive polymer flocculant solutions backed by decades of water treatment experience.

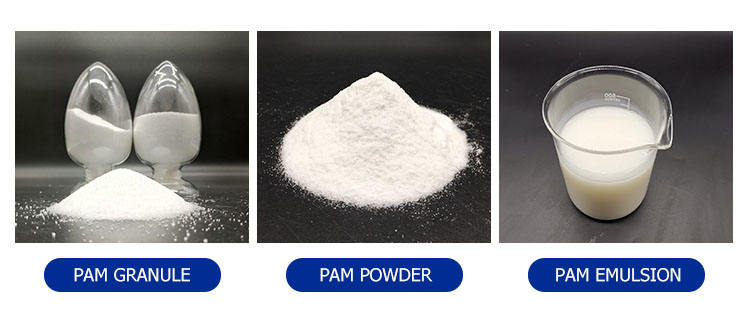

Our extensive polymer flocculant portfolio includes high-performance polyacrylamide products optimized for diverse applications. From municipal water treatment to industrial process optimization, our technical team provides customized solutions addressing your specific treatment challenges.

Ready to Optimize Your Water Treatment with Premium Polymer Flocculants?

Contact our technical experts for personalized polymer flocculant recommendations and complimentary jar testing services.

Get Expert ConsultationConclusion

Polymer flocculants represent indispensable tools in modern water treatment, offering superior performance, cost efficiency, and environmental benefits compared to traditional treatment methods. Understanding polymer flocculant types, mechanisms, and application principles enables water treatment professionals to optimize their processes and achieve consistently excellent results.

As treatment challenges evolve and sustainability requirements intensify, polymer flocculant technology continues advancing to meet industry needs. Partnering with experienced suppliers like Tairan Chemical ensures access to cutting-edge polymer solutions and technical expertise necessary for treatment success.

Whether upgrading existing treatment systems or designing new facilities, incorporating advanced polymer flocculants delivers measurable improvements in water quality, operational efficiency, and environmental compliance. The future of water treatment relies on intelligent application of polymer flocculant technology to address our most pressing water challenges.