What is PAC Used For? Optimizing Poly Aluminium Chloride PAC in Wastewater Treatment

Engineer-focused guidance for getting the most from Poly aluminium chloride pac. As a highly efficient coagulant, its proper use is critical for wastewater treatment. This guide explores the key advantages of pac, grade selection, dosing rates, and field-proven tweaks for optimizing this efficient water treatment chemical.

PAC at a Glance

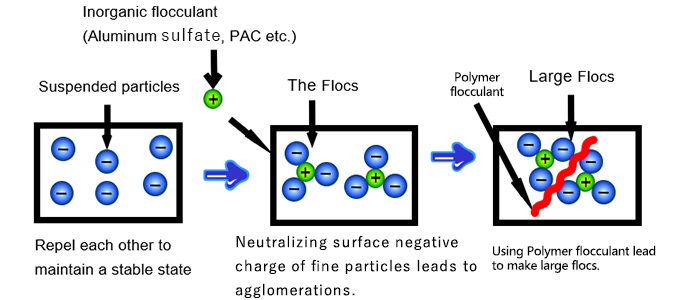

Polyaluminium Chloride (PAC), also known as chloride pac, is a high-charge-density, pre-hydrolyzed inorganic coagulant. It is a key efficient water treatment chemical designed to destabilize colloids (like suspended matter) and accelerate solid–liquid separation. For technical background and purchasing specs (28–30% Al2O3, basicity ranges), see our PAC product page and this practical uses guide.

Common Pitfalls That Increase Cost

1) Over-diluted or over-aged stock

Very low concentration (<1%) or long holding time reduces effective charge. Keep dilution consistent (typ. 5–10%) and use fresh batches. See our comprehensive PAC guide.

2) Wrong basicity for the matrix

High-basicity PACs improve charge neutralization at neutral pH; low-basicity grades can help with highly colored or low-alkalinity waters. Match grade to matrix (details below).

3) Suboptimal injection point

Feed into a zone with vigorous initial mixing (G-value high), followed by tapered flocculation. Poor mixing wastes coagulant and generates fragile flocs.

4) Ignoring PAM synergy

PAC handles destabilization; a tailored PAM flocculant bridges particles for faster settling and denser sludge—often reducing total chemical cost.

Optimizing PAC Dosing Rates & Dosing Systems

Achieving high coagulation efficiency depends on precise dosing. While jar tests set the baseline, real-world optimization involves your dosing systems. This includes dosing pumps (peristaltic or diaphragm), tanks, and mixers, all of which must be calibrated to the plant's flow rate.

Start with jar tests, then confirm on-line with stepped trials. Typical starting dosing rates for industrial water treatment:

| Matrix | Starting Dose (as PAC) | Notes |

|---|---|---|

| Colored, humic-rich (textile/dye) | 30–80 mg/L | Consider lower basicity PAC for color; add an anionic PAM for bridging. |

| Oily/metal-bearing (machining, plating blend) | 40–100 mg/L | pH 6.0–7.5 typical. Follow with CPAM if sludge shear is high. |

| Mining/aggregate high-TSS (Suspended Solids) | 20–60 mg/L | Coarse solids settle; optimize mixer time, then low-dose PAM for compaction. |

Working Example

Plant flow (flow rate): 500 m³/h; trial dose: 50 mg/L PAC (as product).

Hourly PAC mass = 500 × 50 g = 25,000 g/h = 25 kg/h.

If using 10% w/w solution, solution flow ≈ 250 kg/h (≈250 L/h).

Choosing the Right PAC Grade (Basicity & Al2O3)

Basicity reflects the degree of pre-hydrolysis during pac production. In practice:

Low basicity (≤40%) — stronger acid neutralization; effective for high color/low alkalinity waters (textiles, surface color).

Medium basicity (45–65%) — balanced CT removal; good general-purpose coagulant for mixed industrial effluents.

High basicity (≥70%) — highly efficient at near-neutral pH, lower sludge volume, often better cold-water performance.

Compare specs and certificates on the PAC 28–30% Al₂O₃ page, and see deep dives here: PAC Water Treatment Guide.

Pairing PAC with PAM for Faster, Denser Clarification

PAC neutralizes particle charge; polyacrylamide (PAM) creates polymer bridges for robust flocs. Best practice:

Order of addition: PAC first in high-G rapid mix (<30 s), then PAM in tapered flocculation zones.

PAM type: Anionic PAM for mineral/neutral surfaces; cationic PAM for organic-rich or biological sludges.

Make-down: PAM at 0.1–0.2% w/w; age 30–60 min before dosing to maximize chain extension.

Industry Snapshots (SEA & MENA)

Textile & Dyeing (Color + COD)

Switch from alum to medium-basicity PAC cut dose ~25% and improved color removal (>90%). Final polish achieved with low-dose anionic PAM.

Food Processing (Fat/Oil/Grease)

PAC at neutral pH improved organics capture; adding CPAM (0.5–1.5 mg/L) produced shear-resistant flocs for DAF + clarifier trains.

Mining & Aggregates (High TSS)

Low–mid dose PAC stabilized fines and suspended solids; small PAM trim dose increased settling velocity and raised underflow solids for faster dewatering.

Troubleshooting Cheatsheet

| Symptom | Likely Cause | Action |

|---|---|---|

| Flocs too small / slow settling | Under-dosing PAC; PAM added too early or too diluted | Increase PAC in small steps; move PAM downstream; check PAM make-down age |

| Pin-floc carryover | Excess shear; wrong PAM charge type | Reduce mixer G; trial anionic vs cationic PAM; verify pH 6–7.5 |

| Rising sludge / blanket | Gas formation; sludge too light | Improve sludge withdrawal; add PAM trim; check nutrient/biogas disturbance |

| Seasonal performance drop | Cold water viscosity; low alkalinity | Consider higher-basicity PAC; ensure alkalinity support; insulate lines |

For full mechanisms and selection flowcharts, review the Comprehensive PAC Guide.

Need a PAC–PAM dosing plan tailored to your plant?

Share your flow, pH/alkalinity, turbidity/SS, and current chemicals. We’ll return a jar-test matrix and starting setpoints.

FAQ

What is the typical pH window for PAC?

Most industrial matrices perform well around pH 6.0–7.5. Low alkalinity streams may need lime/soda support.

Should I pick liquid or powder PAC?

Powder eases long-distance logistics; liquid saves handling time onsite. See spec and logistics notes on the PAC product page.

Do I always need PAM with PAC?

No, but PAM often delivers faster settling and drier sludge. Explore anionic PAM options for mineral-rich waters.