Choosing between Polyaluminum Chloride (PAC) and Aluminum Sulfate (Alum) is one of the most important decisions for water treatment facilities. While both are aluminum-based coagulants that remove turbidity and contaminants, they differ significantly in performance, cost-effectiveness, and operational complexity. This comprehensive guide provides data-driven comparisons, real-world cost analyses, and a practical decision framework to help you select the optimal coagulant for your application.

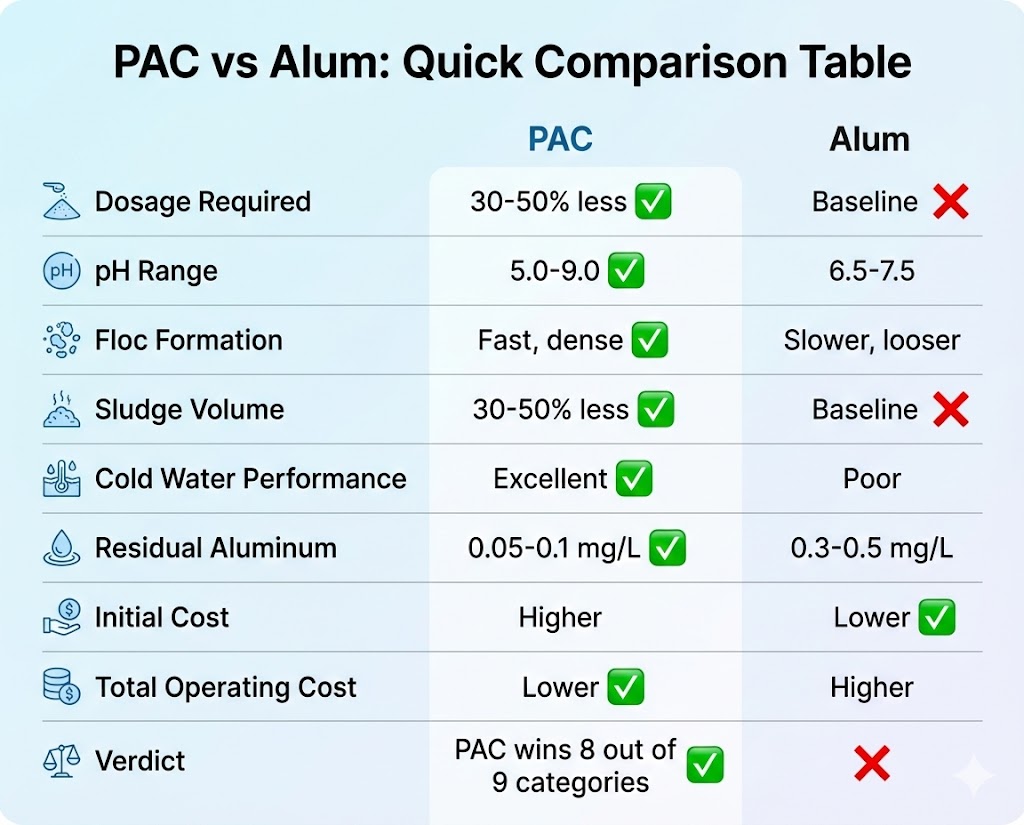

| Factor | PAC | Alum | Winner |

|---|---|---|---|

| Dosage Required | 30-50% less | Baseline | PAC ✅ |

| pH Range | 5.0-9.0 | 6.5-7.5 | PAC ✅ |

| Floc Formation | Fast, dense | Slower, looser | PAC ✅ |

| Sludge Volume | 30-50% less | Baseline | PAC ✅ |

| Cold Water Performance | Excellent | Poor | PAC ✅ |

| Residual Aluminum | 0.05-0.1 mg/L | 0.3-0.5 mg/L | PAC ✅ |

| Initial Cost | Higher | Lower | Alum ✅ |

| Total Operating Cost | Lower | Higher | PAC ✅ |

Verdict: PAC wins 8 out of 9 categories, making it the superior choice for most applications.

Chemical Name: Aluminum Sulfate [Al₂(SO₄)₃]

Form: White crystalline solid, easily soluble

How It Works:

1. Dissolves in water, releasing Al³⁺ ions

2. Hydrolyzes to form aluminum hydroxide [Al(OH)₃]

3. Forms flocs that trap suspended particles

Key Characteristics:

● Simple inorganic salt

● Traditional coagulant (used for 100+ years)

● Acidic (pH 3.0-3.5 in solution)

● Widely available globally

Chemical Name: Polyaluminum Chloride [Alₙ(OH)ₘCl₍₃ₙ₋ₘ₎]

Form: Yellow/white powder or liquid, various grades

How It Works:

1. Pre-hydrolyzed aluminum polymer

2. Already contains multi-core hydroxy-aluminum complexes

3. Rapid charge neutralization upon addition

4. Forms large, dense flocs through bridging

Key Characteristics:

● Advanced inorganic polymer

● Pre-polymerized structure

● Less acidic (pH 4.0-5.0)

● Higher charge density

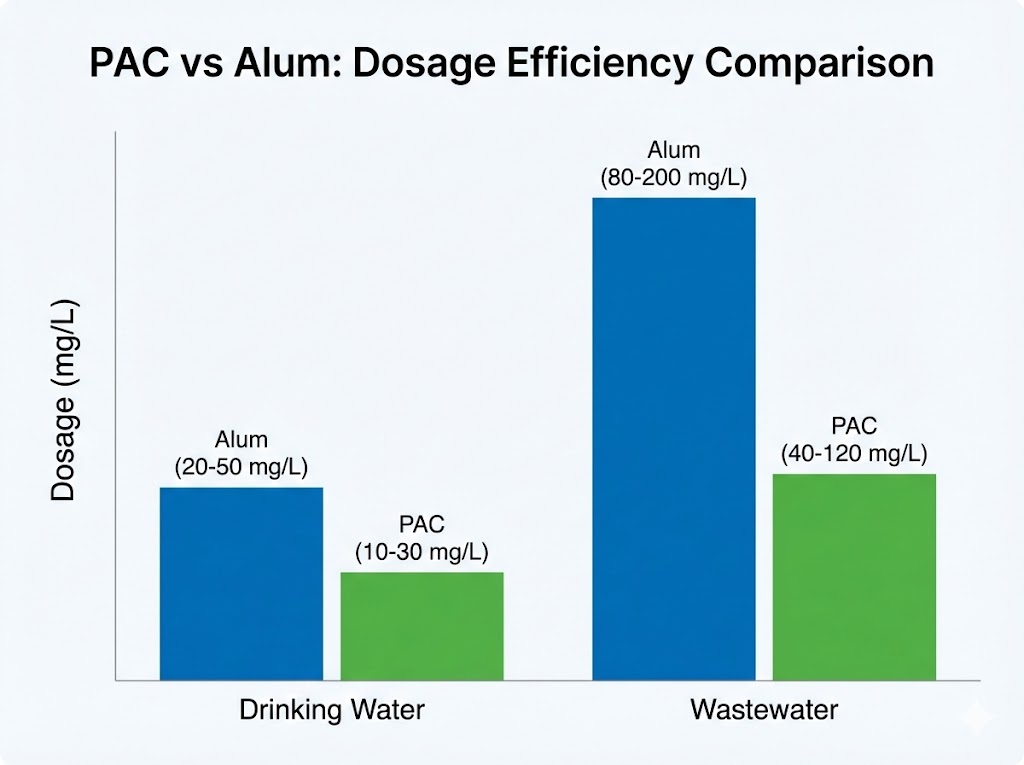

Alum Typical Dosage:

● Drinking water: 20-50 mg/L

● Wastewater: 80-200 mg/L

● High turbidity: 100-300 mg/L

PAC Typical Dosage:

● Drinking water: 10-30 mg/L (50% less)

● Wastewater: 40-120 mg/L (50% less)

● High turbidity: 50-180 mg/L (40% less)

Why PAC Uses Less:

● Higher aluminum content (30% vs 8% in alum)

● Pre-polymerized structure more efficient

● Higher charge density

Example Calculation:

For 10,000 m³/day at 30 NTU turbidity:

Alum Required: 10,000 m³ × 40 mg/L = 400 kg/day PAC Required: 10,000 m³ × 20 mg/L = 200 kg/day Chemical Savings: 200 kg/day = 50%

Alum:

● Optimal pH: 6.5-7.5 (narrow window)

● Performance drops sharply outside this range

● Significantly lowers water pH (typically 0.5-1.5 units)

● Usually requires pH adjustment with lime/caustic

PAC:

● Optimal pH: 5.0-9.0 (wide window)

● Consistent performance across broader range

● Minimal pH impact (typically 0.1-0.3 units)

● Rarely requires pH adjustment

Cost Implications:

Water plant treating 5,000 m³/day:

Alum Scenario: - pH drops from 7.5 to 6.0 - Lime needed: 20 mg/L = 100 kg/day - Lime cost: 100 kg × $0.20 = $20/day - Annual lime cost: $7,300 PAC Scenario: - pH drops from 7.5 to 7.3 - No pH adjustment needed - Annual savings: $7,300

Floc Formation Speed:

| Stage | Alum | PAC |

|---|---|---|

| Rapid mix time | 1-2 min | 1-2 min |

| Slow mix time | 20-30 min | 15-20 min |

| Settling time | 3-4 hours | 2-3 hours |

| Total Treatment Time | ~4 hours | ~3 hours |

Floc Characteristics:

Alum Flocs:

● Smaller size (0.5-2 mm)

● Lighter, fluffier structure

● Settling velocity: 0.5-1.0 m/hr

● Easily disrupted by mixing

PAC Flocs:

● Larger size (2-5 mm)

● Dense, compact structure

● Settling velocity: 1.5-3.0 m/hr

● More resistant to shear

Impact on Plant Capacity:

For existing clarifier (surface area 100 m²):

With Alum: Overflow rate: 1.0 m/hr max Capacity: 100 m² × 1.0 m/hr × 24 hr = 2,400 m³/day With PAC: Overflow rate: 2.0 m/hr possible Capacity: 100 m² × 2.0 m/hr × 24 hr = 4,800 m³/day Capacity Increase: 100% with PAC

Volume Reduction:

Treating 10,000 m³/day with 100 NTU turbidity:

Alum: - Coagulant: 50 mg/L - pH adjustment: 25 mg/L lime - Total chemicals: 75 mg/L - Sludge: 750 kg dry solids/day PAC: - Coagulant: 25 mg/L - No pH adjustment - Total chemicals: 25 mg/L - Sludge: 400 kg dry solids/day Sludge Reduction: 47%

Sludge Disposal Cost Impact:

Annual Sludge (Alum): 274 tons Disposal cost: $100/ton = $27,400/year Annual Sludge (PAC): 146 tons Disposal cost: $100/ton = $14,600/year Annual Savings: $12,800

Performance at Different Temperatures:

| Temperature | Alum Efficiency | PAC Efficiency |

|---|---|---|

| >20°C | 100% (baseline) | 100% |

| 10-20°C | 70-85% | 95-100% |

| 5-10°C | 50-70% | 85-95% |

| <5°C | 30-50% | 70-85% |

Why This Matters:

Cold water plants often must:

● With Alum: Increase dose 50-100% in winter

● With PAC: Increase dose only 10-20% in winter

Example (Northern climate plant):

Summer (25°C): Alum: 30 mg/L, PAC: 15 mg/L Winter (5°C): Alum: 60 mg/L (100% increase) PAC: 18 mg/L (20% increase) Winter Chemical Cost Difference: Alum: Double the cost PAC: Nearly same cost

Typical Residual Levels:

| Coagulant | Treated Water Al Residual | WHO Guideline |

|---|---|---|

| Alum | 0.3-0.5 mg/L | <0.2 mg/L |

| PAC | 0.05-0.1 mg/L | <0.2 mg/L |

Compliance:

● Alum: Often exceeds guideline, requires optimization

● PAC: Consistently meets guideline

Health & Regulatory Implications:

● Lower residual aluminum reduces health concerns

● Easier regulatory compliance

● Better for sensitive populations

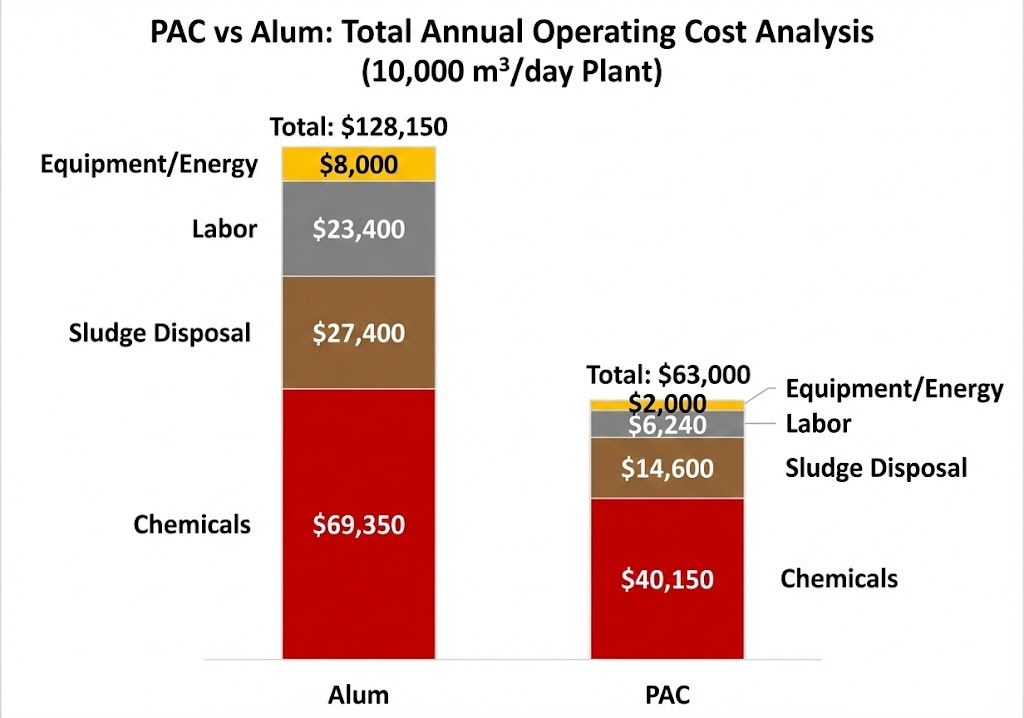

Alum:

Alum dose: 40 mg/L Price: $350/ton Daily cost: 10,000 × 40 / 1,000,000 × $350 = $140 Lime (pH adjustment): 25 mg/L Price: $200/ton Daily cost: 10,000 × 25 / 1,000,000 × $200 = $50 Total Chemical: $190/day = $69,350/year

PAC:

PAC dose: 20 mg/L Price: $550/ton Daily cost: 10,000 × 20 / 1,000,000 × $550 = $110 pH adjustment: None needed Total Chemical: $110/day = $40,150/year Chemical Savings: $29,200/year

Alum Sludge: 274 tons/year × $100 = $27,400 PAC Sludge: 146 tons/year × $100 = $14,600 Sludge Savings: $12,800/year

Alum: - Frequent pH monitoring/adjustment: +10 hr/week - Sludge handling: +5 hr/week - Total: 15 hr/week × 52 × $30/hr = $23,400/year PAC: - Minimal pH adjustment: +2 hr/week - Less sludge: +2 hr/week - Total: 4 hr/week × 52 × $30/hr = $6,240/year Labor Savings: $17,160/year

Alum: - Higher corrosion = $5,000/year maintenance - Longer treatment time = $3,000/year extra energy PAC: - Lower corrosion = $2,000/year maintenance - Shorter treatment time = standard energy Equipment Savings: $6,000/year

| Cost Category | Alum | PAC | Savings |

|---|---|---|---|

| Chemicals | $69,350 | $40,150 | $29,200 |

| Sludge Disposal | $27,400 | $14,600 | $12,800 |

| Labor | $23,400 | $6,240 | $17,160 |

| Equipment/Energy | $8,000 | $2,000 | $6,000 |

| TOTAL | $128,150 | $63,000 | $65,150 |

Annual Savings with PAC: $65,150 (51% reduction)

Payback Period:If switching requires $20,000 investment → Payback in 3.7 months

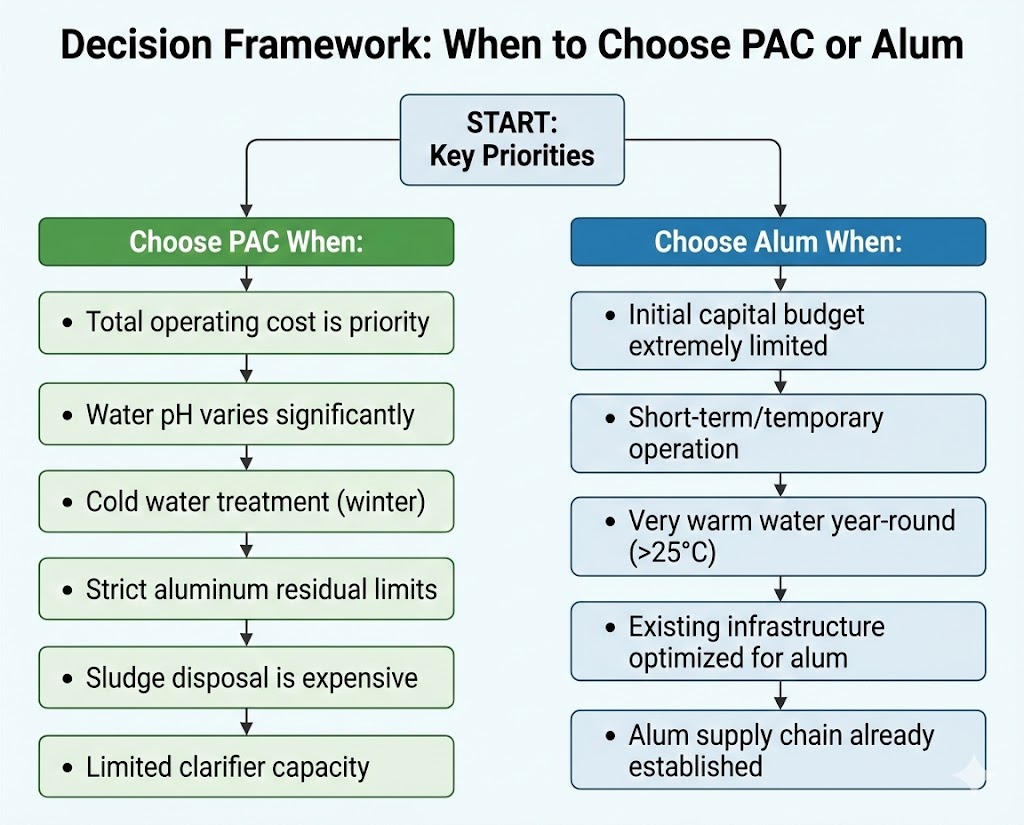

✅ Total operating cost is priority✅ Water pH varies significantly✅ Cold water treatment (winter operations)✅ Strict aluminum residual limits✅ Sludge disposal is expensive✅ Limited clarifier capacity (need higher overflow rates)✅ Automation/minimal operator attention desired✅ Long-term (5+ year) operation planned

✅ Initial capital budget extremely limited✅ Short-term/temporary operation✅ Very warm water year-round (>25°C)✅ Existing infrastructure optimized for alum✅ Alum supply chain already established✅ No access to quality PAC supplier

Phase 1: Testing (2-4 weeks)

1.Obtain PAC Samples

● Request 3-5 different PAC grades

● Specify your application (drinking water, wastewater, etc.)

2.Conduct Jar Tests

● Test current water with both alum and PAC

● Record optimal doses, floc formation time, clarity

● Measure residual aluminum

3.Pilot Testing (if possible)

● Run side-by-side for 1-2 weeks

● Compare actual plant performance

● Monitor all parameters

Phase 2: Preparation (1-2 weeks)

4.Equipment Assessment

● Check chemical storage compatibility

● PAC requires corrosion-resistant tanks (HDPE, PP, FRP)

● Verify metering pump compatibility

5.Staff Training

● Prepare new dosing calculations

● Update SOPs

● Train operators on different characteristics

6.Procurement

● Order initial PAC supply

● Negotiate pricing (bulk discounts)

● Arrange delivery schedule

Phase 3: Implementation (1 week)

7.Initial Switchover

● Start at 50% of jar test optimal dose

● Monitor closely for first 24 hours

● Adjust based on performance

8.Optimization

● Fine-tune dose over 3-7 days

● Eliminate pH adjustment if possible

● Document new optimal parameters

Phase 4: Monitoring (Ongoing)

9.Regular Testing

● Weekly jar tests initially

● Monthly after stabilization

● Track all cost savings

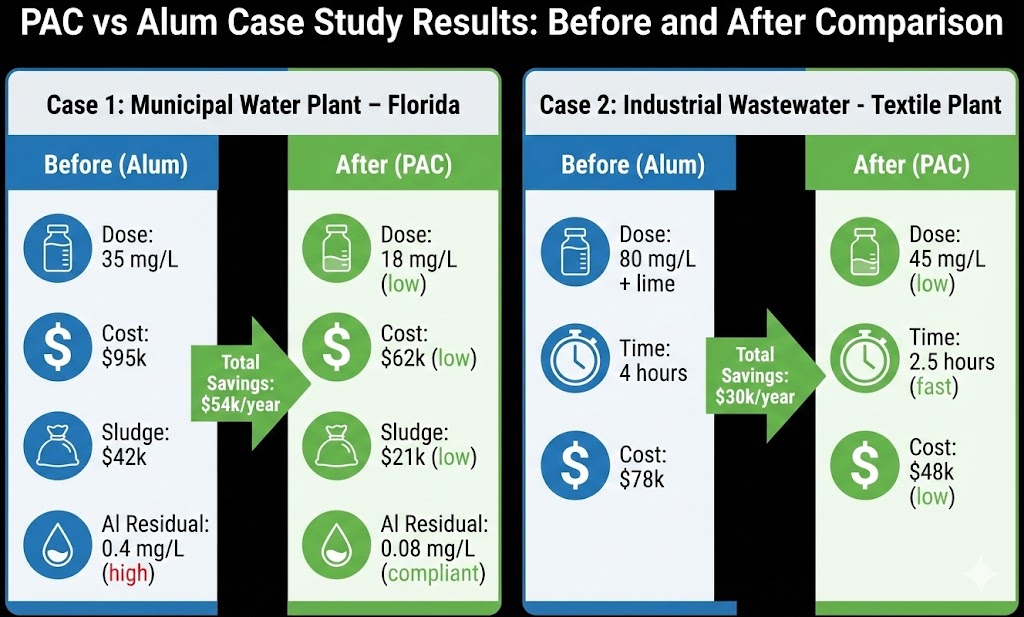

Before (Alum):

● Capacity: 15,000 m³/day

● Alum dose: 35 mg/L

● Annual chemical cost: $95,000

● Sludge disposal: $42,000/year

● Aluminum residual: 0.4 mg/L (above limit)

After (PAC):

● Same capacity

● PAC dose: 18 mg/L

● Annual chemical cost: $62,000

● Sludge disposal: $21,000/year

● Aluminum residual: 0.08 mg/L (compliant)

Results:

● Total savings: $54,000/year (36%)

● Payback period: 4.5 months

● Regulatory compliance achieved

● Operator workload reduced 40%

Before (Alum):

● Flow: 5,000 m³/day

● Alum: 80 mg/L + lime 40 mg/L

● Treatment time: 4 hours

● Annual cost: $78,000

After (PAC):

● Same flow

● PAC: 45 mg/L, no lime

● Treatment time: 2.5 hours

● Annual cost: $48,000

Results:

● Savings: $30,000/year (38%)

● Faster treatment = increased capacity

● Simpler operations

● Better cold-weather performance

❌ Wrong: "We used 40 mg/L alum, so we'll use 40 mg/L PAC"

✅ Right: Start with jar tests, typically need 40-60% less PAC

❌ Wrong: Keep adding lime as before

✅ Right: PAC often eliminates need for pH adjustment, test first

❌ Wrong: Buying cheapest PAC available

✅ Right: Match PAC grade (basicity, Al content) to application

❌ Wrong: Switch without operator training

✅ Right: Comprehensive training on different behavior

❌ Wrong: Switch based on sales pitch alone

✅ Right: Always conduct jar tests and pilot trials

Q: Is PAC safe for drinking water?

A: Yes. PAC is approved by WHO and NSF for potable water. Produces lower aluminum residuals than alum.

Q: Can I mix PAC and alum together?

A: Not recommended. Use one or the other. Switching should be complete transition.

Q: How long does PAC solution last?

A: Liquid PAC: 6-12 months. Powder PAC: 18-24 months. Prepared solutions: 24-48 hours.

Q: Will PAC work in my existing equipment?

A: Usually yes, but check material compatibility. PAC is less corrosive than alum.

Q: Is PAC environmentally better than alum?

A: Yes. Less sludge, lower residuals, no sulfate addition, better for aquatic life.

Q: What if PAC costs more per kg?

A: Focus on cost per m³ treated, not per kg. Total operating cost almost always favors PAC.

✅ PAC outperforms alum in 8 out of 9 categories

✅ Total operating cost 30-50% lower with PAC

✅ Faster treatment, less sludge, simpler operations

✅ Better cold-water performance

✅ Lower aluminum residuals for compliance

✅ Payback period typically 3-6 months

The Choice is Clear: For most applications, PAC is the superior coagulant delivering better performance and lower total cost despite higher unit price.

Copyright © 2024 Tairan Chemical. All rights reserved.