Mining operations generate massive volumes of contaminated water containing suspended solids, heavy metals, and chemical residues. Polyacrylamide (PAM) has become the industry standard for treating mining wastewater, offering efficient solid-liquid separation, metal removal, and water recovery. This guide provides practical methods for optimizing PAM use in mining applications.

Mining wastewater presents unique challenges that make PAM essential:

High Solids Concentration: Mine water contains 10,000-100,000 mg/L suspended solids—far exceeding typical wastewater levels. Standard coagulants can't handle this load effectively.

Heavy Metal Contamination: Mining releases arsenic, lead, mercury, copper, and zinc into water. These metals pose serious environmental and health risks requiring specialized treatment.

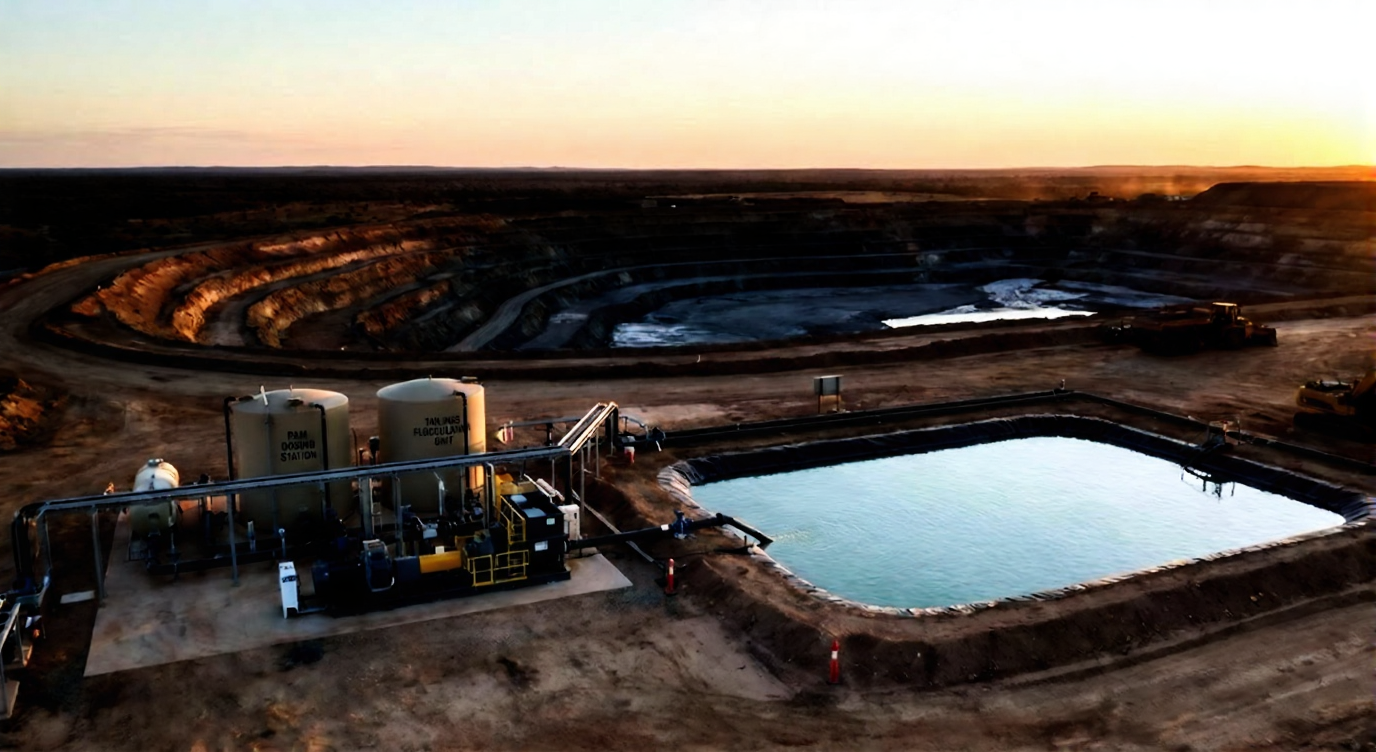

Water Scarcity: Many mines operate in arid regions where water is precious. PAM enables 70-90% water recovery, reducing freshwater consumption and costs.

Regulatory Pressure: Discharge limits for mining wastewater are strict. Failing to meet standards results in hefty fines, operational shutdowns, and environmental damage.

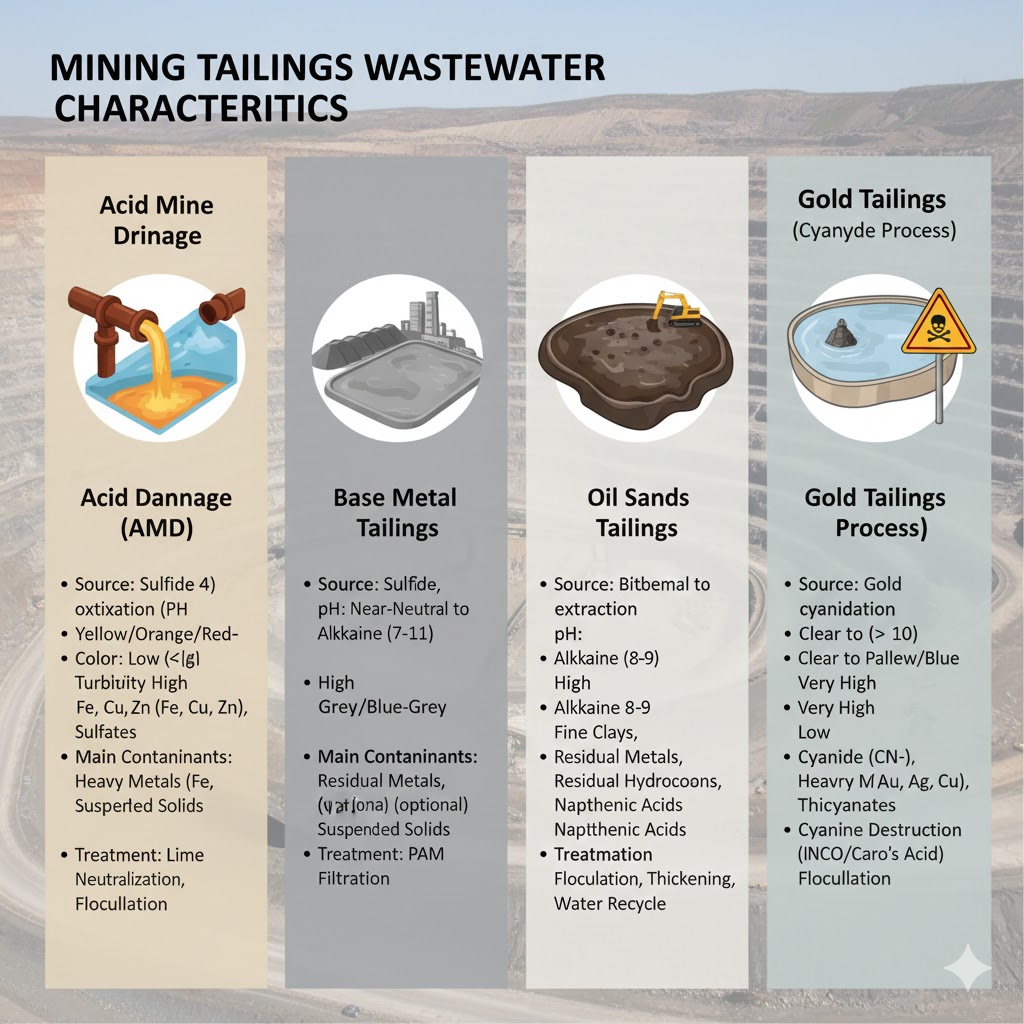

Characteristics:

● Extremely high suspended solids (50,000-200,000 mg/L)

● Fine particle size (1-50 microns)

● pH varies by ore type (acidic for sulfide ores, alkaline for carbonate ores)

● Contains processing chemicals (flotation reagents, grinding aids)

Challenges: Ultra-fine particles resist settling, high water volume, chemical interference

Characteristics:

● Moderate solids (5,000-50,000 mg/L)

● Heavy metal content varies by ore

● Contains grinding media residues

● Recycled multiple times in circuit

Challenges: Accumulated contaminants, water chemistry changes

Characteristics:

● Low pH (2-4) from sulfide oxidation

● High dissolved metals (Fe, Al, Mn, Zn, Cu)

● Sulfate concentration >1,000 mg/L

● Orange/red coloration from iron precipitation

Challenges: Extreme pH, high metal toxicity, continuous generation for decades

Characteristics:

● Lower solids (<5,000 mg/L)

● Groundwater quality influenced by geology

● May contain hydrocarbons from equipment

● Large volumes requiring treatment

Challenges: Variable quality, continuous flow

| Mining Application | Recommended PAM | Molecular Weight | Charge Density |

|---|---|---|---|

| Tailings Thickening | Anionic | 12-18 million | 10-30% |

| Sludge Dewatering | Cationic | 8-12 million | 30-60% |

| Process Water Clarification | Anionic | 10-15 million | 20-40% |

| AMD Neutralization Sludge | Cationic | 10-15 million | 40-60% |

| Coal Washing | Anionic | 15-20 million | 25-35% |

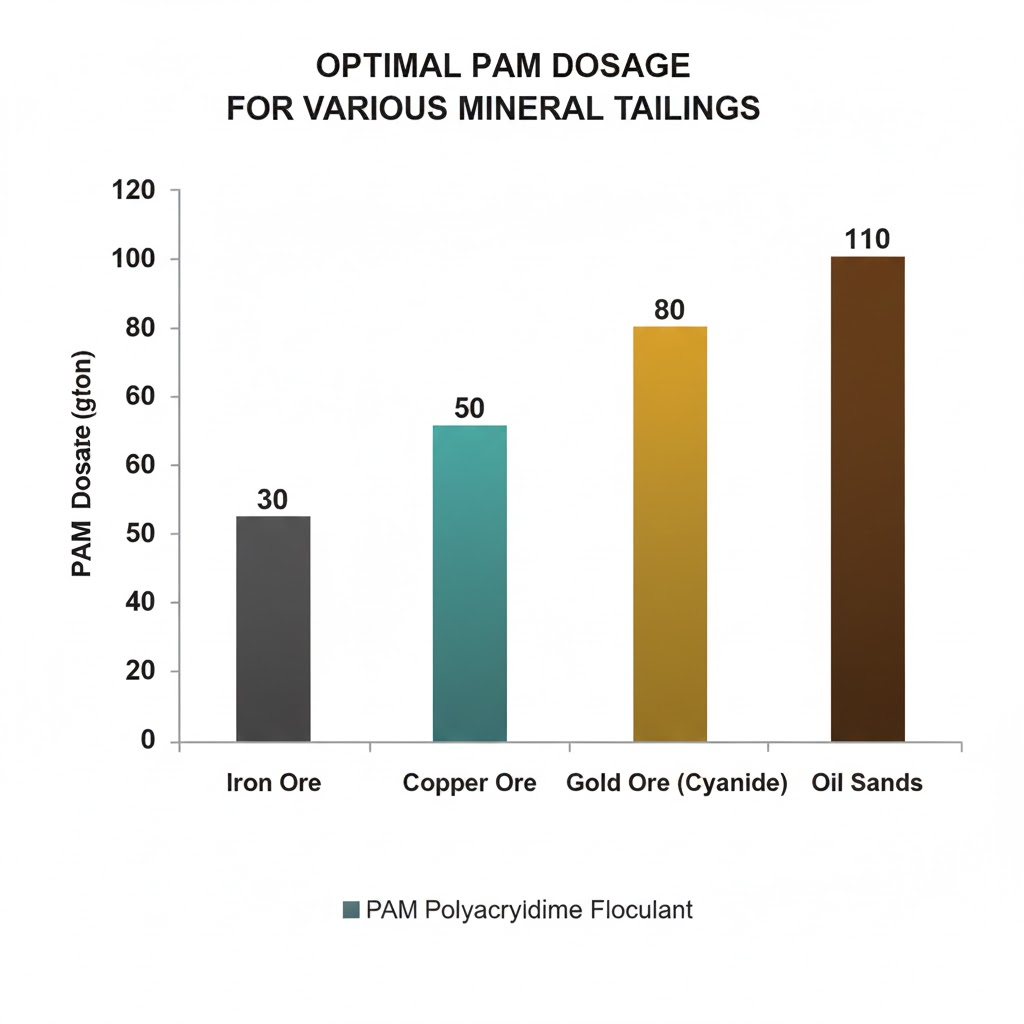

Ore Type Matters:

● Copper/Gold: Anionic PAM, high MW (15-18M)

● Iron Ore: Anionic PAM, medium MW (12-15M)

● Coal: Anionic PAM, very high MW (18-20M)

● Phosphate: Anionic or nonionic, high MW

● Bauxite: Anionic PAM, medium-high MW

pH Optimization:

● pH 6-8: Anionic PAM works best

● pH 4-6: Nonionic PAM more effective

● pH >8: Anionic still effective, may need higher dose

● pH <4 (AMD): Neutralize first, then cationic PAM

Particle Size:

● Very fine (<10 microns): High MW PAM (>15M)

● Medium (10-50 microns): Medium MW (10-15M)

● Coarse (>50 microns): Lower MW acceptable (8-12M)

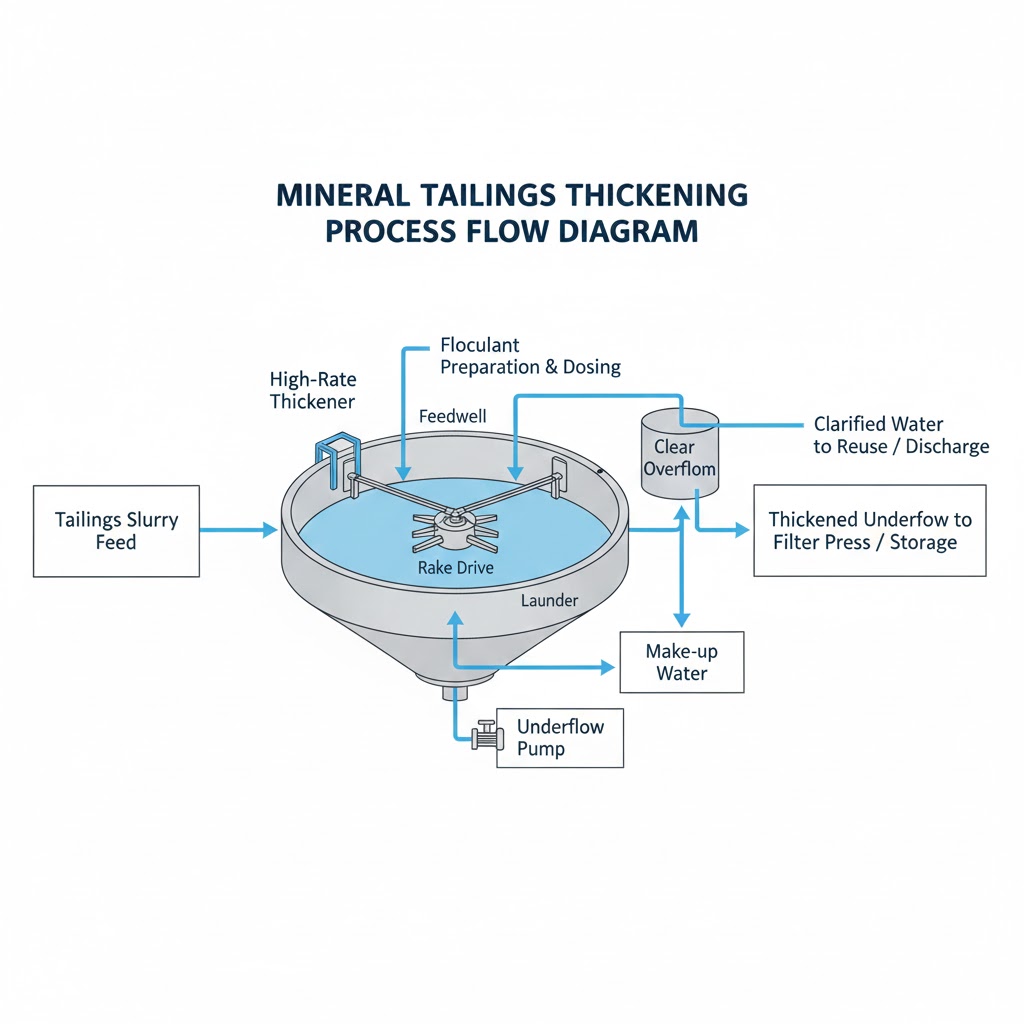

Objective: Concentrate solids from 15-30% to 50-70% for disposal or backfill

Procedure:

Step 1: Prepare PAM Solution

● Dilution: 0.1-0.2% (1-2 kg PAM per 1000L water)

● Aging time: 45-60 minutes

● Use clean water (not process water)

Step 2: Dose Calculation

Typical Range: 20-80 grams PAM per ton of dry solids Start at 40 g/ton, adjust based on settling test

Step 3: Addition Point

● Add to feed well or feed pipe

● Ensure 10-30 seconds retention before thickener

● Use static mixer or turbulent pipe flow

Step 4: Monitor Performance

● Underflow density target: 50-70% solids

● Overflow clarity: <500 mg/L TSS

● Settling rate: Check rake torque

Common Dosages:

● Gold tailings: 30-60 g/ton

● Copper tailings: 40-70 g/ton

● Iron ore tailings: 20-50 g/ton

● Coal tailings: 50-80 g/ton

Objective: Recover process water for reuse, prevent metal loss

Procedure:

Step 1: Jar TestTest 3-6 PAM products at varying doses (10-50 mg/L)

Step 2: Preparation

● 0.05-0.1% solution

● Feed to clarifier inlet

● Mix thoroughly with incoming water

Step 3: Operation

● Typical dose: 5-20 mg/L

● Retention time: 2-4 hours

● Sludge removal: Continuous or batch

Results:

● Turbidity reduction: >90%

● Metal removal: 60-85%

● Water recovery: 85-95%

Objective: Reduce sludge moisture from 85-95% to 60-75%

Procedure:

Step 1: Select Cationic PAM

● Charge density: 30-60%

● MW: 8-12 million

● Test 3-5 products

Step 2: Optimize Dose

Belt Press: 3-8 kg PAM per ton dry solids Filter Press: 2-5 kg/ton Centrifuge: 4-10 kg/ton

Step 3: Conditioning

● Mix PAM with sludge 30-60 seconds before equipment

● Gentle mixing (avoid shear)

● Observe floc formation

Results:

● Cake dryness: 25-40% solids

● Filtrate clarity: <100 mg/L

● Volume reduction: 60-75%

Solids Concentration:

● Higher solids = higher PAM dose

● 10% solids: 30-50 g/ton

● 20% solids: 40-60 g/ton

● 30% solids: 50-70 g/ton

Particle Size Distribution:

● Finer particles need more PAM

● Wide size range needs higher MW PAM

● Single-sized particles: lower dose

Water Chemistry:

● High hardness (>300 mg/L): Increase dose 20-30%

● High salinity (>5,000 mg/L TDS): Use higher MW

● Extreme pH: Adjust pH first, then dose

Signs:

● Poor settling (restabilization)

● Viscous, sticky sludge

● Cloudy overflow

● Increased costs

Solution: Reduce dose 20-30%, retest

Signs:

● Slow settling

● Small, weak flocs

● High overflow turbidity

● Low underflow density

Solution: Increase dose 20-30%, consider higher MW

Don't Always Choose Cheapest:

Example calculation for 1,000 ton/day tailings:

Low-Cost PAM: $3.50/kg, dose 70 g/ton

● Daily cost: (1,000 × 70 / 1000) × $3.50 = $245/day

Premium PAM: $4.50/kg, dose 45 g/ton

● Daily cost: (1,000 × 45 / 1000) × $4.50 = $203/day

Savings: $42/day = $15,330/year with premium product

Too Concentrated (>0.2%):

● Difficult to dose accurately

● Viscosity issues

● Uneven mixing

Too Dilute (<0.05%):

● Large volumes to handle

● Degradation in storage

● High pumping costs

Optimal: 0.1-0.15% for most mining applications

Reusing clarified water saves:

● Freshwater costs

● Pumping energy

● Environmental discharge fees

Example: 10,000 m³/day mine water

● 85% recovery = 8,500 m³/day reused

● At $0.50/m³: $4,250/day savings

● Annual: $1.55 million

For difficult tailings:

1. Primary: Lower-cost anionic PAM (bulk flocculation)

2. Secondary: Small dose high-performance PAM (floc strengthening)

Total cost often 20-30% lower than single high-dose system

Cold Weather (<10°C):

● Increase dose 15-25%

● Use warmer preparation water

● Extend mixing time

Hot Weather (>30°C):

● Prepare fresh solution daily

● Store in cool location

● Reduce dose 10-15% if performance improves

Typical mining wastewater discharge limits:

| Parameter | Limit | PAM Treatment Result |

|---|---|---|

| TSS | <50 mg/L | 10-30 mg/L ✅ |

| Heavy Metals | Varies | 60-90% removal ✅ |

| pH | 6-9 | Adjust before PAM |

| COD | <100 mg/L | Usually compliant ✅ |

Safe Levels:

● PAM residual in treated water: <0.5 mg/L (typically achieved)

● Acrylamide monomer: <0.0005 mg/L (quality PAM products)

● Non-toxic to aquatic life at normal use levels

PAM-treated sludge:

● Generally non-hazardous (verify with local regulations)

● Can be used for mine backfill

● Reduced leaching compared to untreated tailings

● More stable, less erosion

Problem: High overflow turbidity, low underflow density

Causes & Solutions:

1. Wrong PAM type

● Solution: Test anionic vs. cationic

● Try higher molecular weight

2. Insufficient dose

● Solution: Increase 20-30%

● Check dilution accuracy

3. Poor mixing

● Solution: Verify addition point

● Ensure adequate retention time

4. Water chemistry change

● Solution: Check pH, hardness, temperature

● Adjust PAM type or dose

Problem: Filter press or centrifuge filtrate cloudy

Causes & Solutions:

1. Underdosing

● Solution: Increase cationic PAM 15-25%

2. Insufficient conditioning time

● Solution: Extend to 60-90 seconds

3. Excessive shear

● Solution: Reduce mixing intensity

● Check pump type and speed

Problem: Using more PAM than expected

Causes & Solutions:

1. Solids spike

● Solution: Monitor feed consistency

● Install flow-proportional dosing

2. Degraded solution

● Solution: Prepare fresh daily

● Check storage conditions

3. Equipment malfunction

● Solution: Calibrate metering pump

● Verify dilution system

Challenge: 50,000 ton/day tailings, fine particles, high water loss

Solution:

● Anionic PAM, 18M MW, 25% charge

● Dose: 45 g/ton (down from 65 g/ton with old product)

● Improved thickener design

Results:

● Underflow: 68% solids (was 55%)

● Water recovery: 92% (was 78%)

● PAM cost savings: $180,000/year

● Reduced water makeup: $650,000/year

Challenge: AMD neutralization sludge dewatering

Solution:

● Cationic PAM, 12M MW, 50% charge

● Dose: 6 kg/ton dry solids

● Filter press operation

Results:

● Cake: 38% solids (was 25%)

● Filtrate: <50 mg/L TSS (was 200 mg/L)

● Landfill volume reduction: 55%

● Annual savings: $420,000

● Wear dust mask (N95 minimum)

● Use in ventilated area

● Avoid skin contact (wear gloves)

● Clean spills immediately (very slippery when wet)

● Non-toxic but slippery

● Can cause temporary digestive upset if swallowed

● Rinse eyes immediately if contact occurs

● Keep preparation area well-lit and slip-proof

● Prevent spills into waterways

● Store away from extreme heat (>40°C)

● Keep containers sealed when not in use

● Dispose of expired product per regulations

Q: Can I use the same PAM for tailings and dewatering?

A: No. Tailings need anionic PAM, dewatering needs cationic. Wrong type gives poor results.

Q: Why does PAM work differently in summer vs winter?

A: Cold water slows dissolution and reduces PAM activity. Increase dose 15-25% in winter.

Q: Is PAM safe for the environment?

A: Yes, when used properly. Quality PAM has very low acrylamide monomer content (<0.05%).

Q: How long can I store prepared PAM solution?

A: Maximum 24 hours at room temperature, 72 hours refrigerated. Fresh is always best.

Q: Can PAM remove dissolved metals?

A: No. PAM removes suspended solids. Dissolved metals need chemical precipitation first.

Q: What's the difference between emulsion and powder PAM?

A: Emulsion: faster dissolving, higher cost, shorter storage. Powder: more economical, longer storage, requires proper mixing equipment.

✅ Select Right Type: Anionic for tailings, cationic for dewatering

✅ Optimize Dose: Start with jar tests, adjust for conditions

✅ Monitor Performance: Track settling, clarity, solids content

✅ Control Costs: Use premium products at lower doses

✅ Ensure Compliance: Meet discharge standards consistently

✅ Train Staff: Proper handling ensures safety and performance

Expected Benefits:

● 70-90% water recovery

● 60-85% heavy metal removal

● 30-50% reduced sludge volume

● ROI typically under 12 months

Tairan Chemical supplies mining-grade polyacrylamide worldwide:

Our Mining PAM Products:

● Anionic PAM (10-20 million MW)

● Cationic PAM (8-15 million MW)

● Emulsion and powder forms

● Customized formulations for specific ores

Technical Support:

● Free jar testing and product selection

● On-site optimization assistance

● Dosage calculations and cost analysis

● Training for operations staff

Website: tairanchemical.com

Email: [info@tairanchemical.com]

Phone: [+86 18538555671]

Request samples and quotations

Copyright © 2024 Tairan Chemical. All rights reserved.