Textile manufacturing generates some of the most challenging industrial wastewater—highly colored, high COD, complex chemical composition, and variable flow rates. Polyacrylamide (PAM) offers proven solutions for textile wastewater treatment, achieving 80-95% color removal, 60-80% COD reduction, and enabling water reuse. This guide provides practical methods for optimizing PAM use in textile applications.

Textile wastewater presents unique treatment difficulties:

Intense Color: Even 1 mg/L of dye can cause visible coloration. Textile effluent often contains 100-500 mg/L dye, making it highly visible and aesthetically unacceptable.

High COD: Chemical oxygen demand reaches 1,000-5,000 mg/L from dyeing chemicals, sizing agents, and finishing products—far exceeding discharge limits (typically <100-200 mg/L).

pH Extremes: Processes alternate between acidic (pH 2-4) for acid dyes and alkaline (pH 10-12) for reactive dyes, requiring pH adjustment before treatment.

Variable Composition: Different fabrics (cotton, polyester, nylon) and processes (dyeing, printing, finishing) produce different wastewater characteristics daily.

Recalcitrant Organics: Many textile chemicals resist biological degradation, requiring physicochemical treatment.

Characteristics:

● Intense color (100-500 mg/L dye)

● High COD (1,500-4,000 mg/L)

● Variable pH (2-12)

● Contains salt (20-80 g/L) from dyeing process

● Temperature: 40-95°C

Main Dyes:

● Reactive dyes: Cotton, bright colors, alkaline pH

● Acid dyes: Wool, silk, nylon, acidic pH

● Disperse dyes: Polyester, complex removal

● Vat dyes: Cotton, reduced form colorless, oxidized form colored

Characteristics:

● High starch/PVA content

● COD: 800-2,000 mg/L

● BOD: 400-1,000 mg/L

● Relatively biodegradable

● Lower color (<50 mg/L)

Characteristics:

● Alkaline pH (10-12)

● Contains caustic soda, detergents

● COD: 500-1,500 mg/L

● Oils, waxes, pectins

● Lower color (brownish)

Characteristics:

● High color intensity

● Contains thickeners (guar gum, starch)

● Variable viscosity

● COD: 1,000-3,000 mg/L

● Intermittent discharge

| Dye Type | Dye Charge | Recommended PAM | Molecular Weight | Charge Density |

|---|---|---|---|---|

| Reactive | Anionic | Cationic | 8-12 million | 30-50% |

| Acid | Anionic | Cationic | 10-15 million | 40-60% |

| Direct | Anionic | Cationic | 10-15 million | 30-50% |

| Disperse | Non-ionic | Cationic | 8-12 million | 40-60% |

| Vat | Anionic (in alkaline) | Cationic | 12-18 million | 30-50% |

Cationic PAM (Most Common):

● Best for most textile dyes (which are anionic)

● Excellent color removal (80-95%)

● Effective across pH 6-10

● Charge density: Higher (40-60%) for intense colors

Anionic PAM:

● Used for cationic dyes (rare in textiles)

● Effective for desizing wastewater

● Better for high-salt environments

Nonionic PAM:

● Works across wide pH range (4-11)

● Good for mixed wastewater

● Lower performance than ionic types

Low MW (6-8 million):

● Lower viscosity, easier handling

● Works for smaller particles

● Lower cost

Medium MW (8-12 million):

● Best for most textile applications

● Good balance of performance and cost

● Optimal for reactive and acid dyes

High MW (12-18 million):

● For very fine particles

● Disperse dyes and difficult wastewaters

● Higher cost but better performance

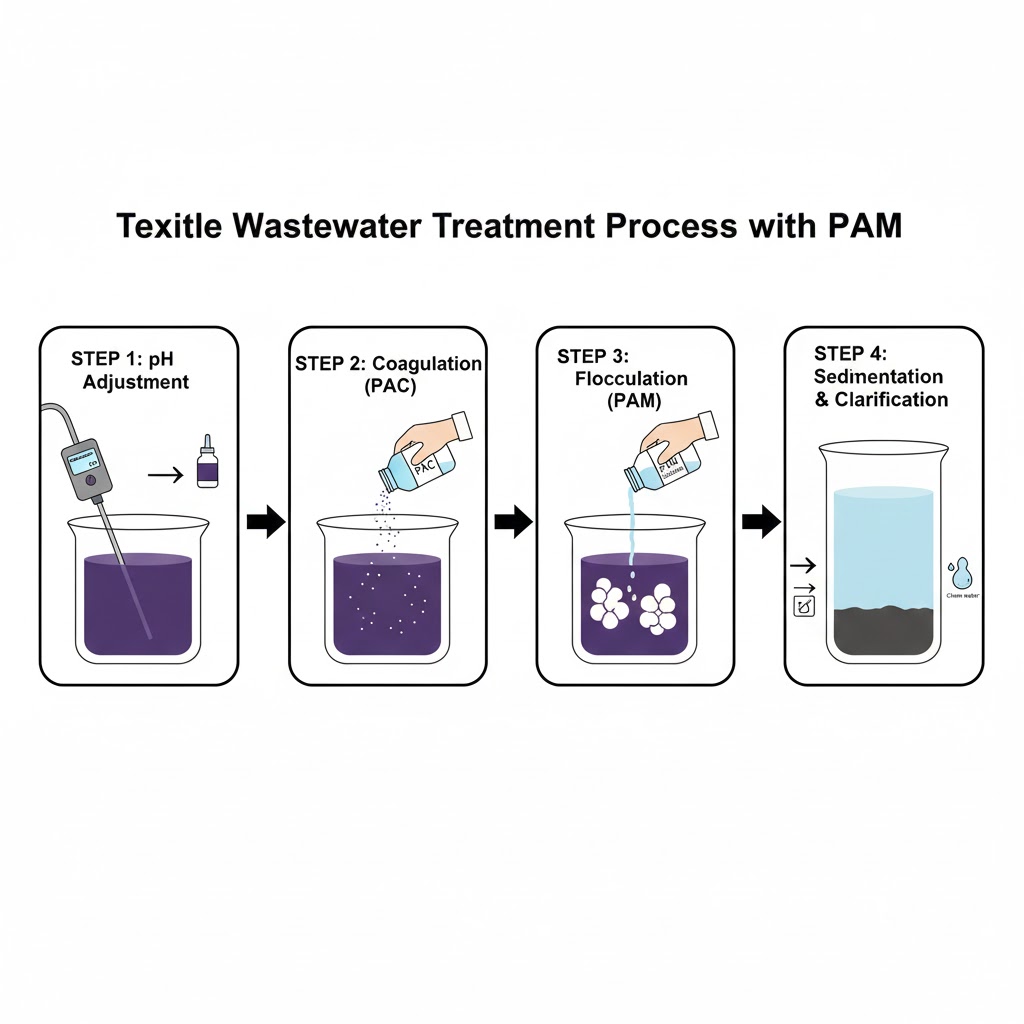

Critical First Step:Textile wastewater pH must be adjusted to 6-8 before PAM addition.

Procedure:

1. Measure influent pH

2. Add acid (H₂SO₄) if pH >8.5

3. Add base (NaOH or lime) if pH <6

4. Mix thoroughly 2-3 minutes

5. Verify pH in optimal range

Typical Chemical Doses:

● Alkaline wastewater (pH 11-12): 500-1,500 mg/L H₂SO₄

● Acidic wastewater (pH 3-4): 300-800 mg/L NaOH/Lime

Use PAC Before PAM:PAC neutralizes charges and destabilizes dye molecules.

Dosage:

● Typical: 100-300 mg/L PAC

● High color: 200-500 mg/L

● Mix: Rapid (200 RPM, 1-2 minutes)

Prepare PAM Solution:

● Dilution: 0.1-0.2% (1-2 kg per 1000L water)

● Aging: 45-60 minutes

● Use clean water for preparation

Dosage Calculation:

Typical Range: 5-30 mg/L PAM Start at 10 mg/L, adjust based on jar test For 1,000 m³/day flow at 15 mg/L: Daily PAM = 1,000 × 15 / 1000 = 15 kg/day

Addition:

● Add PAM solution after PAC

● Gentle mixing: 30-60 RPM, 15-20 minutes

● Observe floc formation

Optimal Floc Characteristics:

● Large, visible flocs (5-10 mm)

● Fast settling (<20 minutes)

● Compact sludge

● Clear supernatant

Clarifier/Settling Tank:

● Retention time: 2-4 hours

● Overflow rate: <1 m/hr

● Sludge removal: Continuous or batch

Alternative Equipment:

● DAF (Dissolved Air Flotation): Best for oily textile wastewater, fibers

● Filter Press: For sludge dewatering

● Centrifuge: High-speed sludge separation

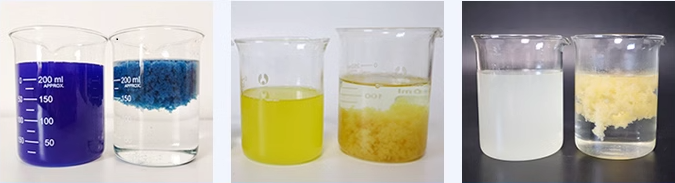

Expected Results:

● Color removal: 80-95%

● COD reduction: 60-80%

● TSS removal: >95%

● Treated water: Clear, pale color

Color Intensity:

● Light color (<100 mg/L): 5-10 mg/L PAM

● Medium color (100-300 mg/L): 10-20 mg/L PAM

● Dark color (>300 mg/L): 20-30 mg/L PAM

COD Level:

● Low COD (<1,000 mg/L): Lower PAM dose

● High COD (>3,000 mg/L): Higher PAM dose

● Each 1,000 mg/L COD requires ~5 mg/L additional PAM

Salt Concentration:High salt (>20 g/L) requires:

● 20-30% more PAM

● Higher charge density PAM (50-60%)

● Better mixing to overcome ionic shielding

Temperature:

● Cold (<15°C): Increase dose 20-30%

● Hot (>40°C): Can reduce dose 10-15%

● Optimal: 20-30°C

Essential for Each Wastewater Batch:

1. Fill 6 beakers with 500 mL sample each

2. Adjust pH to 7.0 in all beakers

3. Add PAC 200 mg/L to all, rapid mix 1 min

4. Add different PAM doses:

● Beaker 1: 5 mg/L

● Beaker 2: 10 mg/L

● Beaker 3: 15 mg/L

● Beaker 4: 20 mg/L

● Beaker 5: 25 mg/L

● Beaker 6: 30 mg/L

1. Slow mix 30 RPM, 15 minutes

2. Settle 20-30 minutes

3. Measure:

● Color (visual or spectrophotometer)

● COD

● pH

● Floc size and settling rate

Select Optimal Dose:

● Best color removal

● Good floc formation

● Economical dose

● Consistent performance

Using PAC before PAM reduces total chemical costs:

Without PAC:

● PAM only: 40-60 mg/L required

● Cost: 40 × $5/kg = $200/ton wastewater

With PAC:

● PAC: 200 mg/L at $0.5/kg = $100/ton

● PAM: 15 mg/L at $5/kg = $75/ton

● Total: $175/ton

● Savings: 12.5%

Plus benefits: Better color removal, more compact sludge

Treating textile wastewater for reuse saves significantly:

Example Calculation:

● Flow: 2,000 m³/day

● Treatment cost: $0.15/m³

● Reuse rate: 70%

● Reused water: 1,400 m³/day

● Freshwater cost: $0.80/m³

Daily savings:= (1,400 × $0.80) - (2,000 × $0.15) = $1,120 - $300 = $820/day

Annual savings: $299,300

For extremely difficult wastewaters:

Primary PAM: Lower-cost cationic, bulk removal

● Dose: 10 mg/L

● Cost: $50/ton wastewater

Secondary PAM: High-performance, polishing

● Dose: 3 mg/L

● Cost: $24/ton wastewater

Total: $74/ton vs. $90/ton single high-dose systemSavings: 18%

Reactive Dye Days (High Alkalinity):

● Use more PAC (250-300 mg/L)

● Less PAM needed (10-15 mg/L)

Acid Dye Days (Acidic):

● Less pH adjustment needed

● Moderate PAC (150-200 mg/L)

● Standard PAM (15-20 mg/L)

Desizing Days (Biodegradable):

● Biological pre-treatment option

● Lower chemical doses

● Potential cost reduction: 30-40%

| Parameter | Limit | PAM Treatment Result |

|---|---|---|

| Color | <50-100 units | 20-50 units ✅ |

| COD | <100-200 mg/L | 150-300 mg/L ⚠️ |

| BOD | <30-50 mg/L | Usually compliant ✅ |

| TSS | <50-100 mg/L | 10-30 mg/L ✅ |

| pH | 6-9 | 6.5-8.0 ✅ |

Note: PAM treats suspended dyes well but dissolved COD may require biological treatment for full compliance.

For stringent discharge standards:

Stage 1: PAC + PAM (Physical-Chemical)

● Color: 90% removal

● COD: 60-70% removal

● TSS: >95% removal

Stage 2: Biological (Activated Sludge/MBR)

● Further COD reduction

● BOD removal

● Nutrient removal

Combined Performance:

● Color: >95% removal ✅

● COD: 85-92% removal ✅

● Full compliance achievable

Causes & Solutions:

1. Wrong PAM type

● Check dye charge (most are anionic)

● Switch to cationic PAM with higher charge density

2. pH not optimized

● Verify pH 6-8 before PAM addition

● Some dyes need specific pH for destabilization

3. Underdosing

● Increase PAM 30-50%

● Increase PAC if color is very intense

4. Dissolved dyes

● PAM removes suspended/colloidal dyes only

● Dissolved reactive dyes need chemical reduction or biological treatment

Causes & Solutions:

1. High dissolved COD

● PAM removes particulate COD (60-70%)

● Dissolved organics need biological treatment

● Consider two-stage treatment

2.Insufficient settling

● Extend settling time to 3-4 hours

● Check overflow rate (<1 m/hr)

● Ensure floc settles completely

3. PAM overdose causing COD

● Reduce PAM dose

● Excess polymer adds to COD

Causes & Solutions:

1. No PAC used

● Always use PAC before PAM

● PAC neutralizes charges, PAM bridges particles

2. Wrong mixing

● Rapid mix after PAC: Too vigorous

● Slow mix after PAM: Too gentle or too short

● Optimize to 30-60 RPM, 15-20 min

3. High salinity

● Increase PAM charge density to 50-60%

● Increase dose 20-30%

Causes & Solutions:

1. Overdosing chemicals

● Optimize through jar tests

● Reduce PAC if overused

2. Wet sludge

● Use cationic PAM for sludge conditioning

● Mechanical dewatering (filter press/centrifuge)

● Target: 20-30% dry solids in cake

Challenge:

● 1,500 m³/day wastewater

● Reactive dyes, intense color (300-500 mg/L)

● COD: 2,500-3,500 mg/L

● Discharge limit: Color <80, COD <200 mg/L

Solution Implemented:

● pH adjustment to 7.0

● PAC: 250 mg/L

● Cationic PAM (12M MW, 40% charge): 18 mg/L

● Settling time: 3 hours

● Biological polishing (activated sludge)

Results:

● Color removal: 92% (Final: 40 units)

● COD reduction: 88% (Final: 180 mg/L)

● TSS: <20 mg/L

● 60% water reuse achieved

● Chemical cost: $0.18/m³

● Annual savings from reuse: $350,000

ROI: 8 months payback period

Handling PAM:

● Wear gloves and goggles

● Powder is very slippery when wet

● Clean spills immediately

● Store in cool, dry place

Wastewater Hazards:

● Dyes can stain skin

● Strong acids/bases in textile wastewater

● Use proper PPE

● Emergency eyewash available

Sludge Disposal:

● Test for heavy metals (some dyes contain chromium)

● Dispose per local regulations

● May be hazardous waste if metal content high

Q: Can PAM remove all types of textile dyes?

A: PAM removes suspended and colloidal dyes (80-95%). Dissolved dyes need additional treatment like adsorption or biological processes.

Q: Why is PAC needed before PAM?

A: PAC neutralizes charges and destabilizes dyes. PAM then bridges particles to form flocs. Using PAM alone is less effective.

Q: Can treated water be reused?

A: Yes, 60-80% water reuse is achievable with proper treatment, significant cost savings.

Q: What if color is still visible after treatment?

A: May need advanced treatment: activated carbon, ozone, or biological color removal for dissolved dyes.

Q: Does PAM work for polyester dyeing wastewater?

A: Yes, but disperse dyes (for polyester) are more difficult. Use higher MW PAM (12-15M) and higher doses.

Q: How to reduce sludge volume?

A: Optimize chemical doses, use mechanical dewatering (filter press), add cationic PAM for conditioning.

✅ Adjust pH first (6-8 range critical)

✅ Use PAC + PAM combination (better than PAM alone)

✅ Cationic PAM for most dyes (most textile dyes are anionic)

✅ Jar test every batch (wastewater varies daily)

✅ Optimize for water reuse (60-80% achievable)

✅ Consider two-stage treatment (for strict discharge limits)

Expected Benefits:

● 80-95% color removal

● 60-80% COD reduction

● 60-80% water reuse potential

ROI typically 6-12 months

Tairan Chemical supplies textile-grade polyacrylamide worldwide:

Our Textile PAM Products:

● Cationic PAM (8-15 million MW)

● Various charge densities (20-60%)

● Powder and emulsion forms

● Customized for different dye types

● Free jar testing for your wastewater

● On-site process optimization

● Dosage calculations and cost analysis

● Training for operations staff

Copyright © 2024 Tairan Chemical. All rights reserved.